Corrugated cardboard boxes may look simple, but behind every shipping carton or luxury rigid box is a production chain that blends paper science, engineering, और स्थिरता. For brands and manufacturers in Australia, यूरोप, और उत्तरी अमेरिका, understanding how these boxes are made can guide smarter packaging choices—and avoid costly mistakes.

Raw Materials The Foundation of Every Box

The journey begins with paper. Corrugated boxes combine two layers:

- Kraft linerboard – smooth, strong surfaces that protect the outside. Usually made from long-fibre softwoods such as pine or spruce.

- Fluting medium – the inner wavy sheet that absorbs shocks. Often sourced from recycled paper to balance durability with eco-performance.

In North America, more than 90% of corrugated packaging already contains recycled content, according to the Fibre Box Association. That makes it one of the most circular materials in modern packaging.

पर PACKCCP, we work with FSC-certified paper mills so clients can highlight sustainability credentials without compromising quality. This matters especially in regions like Scandinavia, where eco-certification is often a purchasing requirement.

Steam and Adhesives Turning Sheets Into Structure

The strength of corrugated board doesn’t come from thickness alone—it comes from how the layers bond.

- Steam treatment softens the paper, making it flexible enough to shape.

- Starch-based adhesives, usually from corn, are applied to attach the liners and the fluting. These glues are food-safe, biodegradable, and widely used even in packaging for fresh produce or bakery goods.

The result is a lightweight yet resilient board that can hold significant weight without tearing. One Melbourne-based client of packccp, for example, switched from plastic crates to double-wall corrugated for wine exports, cutting costs and gaining eco appeal.

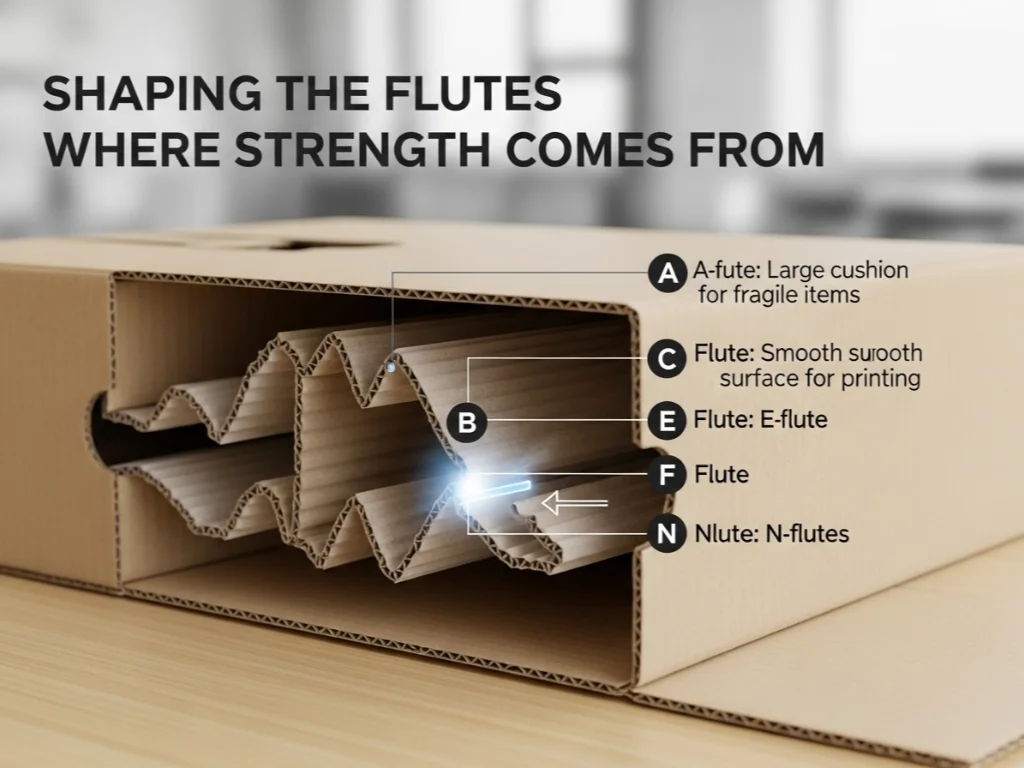

Shaping the Flutes Where Strength Comes From

The “waves” inside corrugated cardboard—called flutes—define its protective power.

- A-flute: thick, with excellent cushioning (used in fragile items).

- B-flute: thinner, better for retail displays.

- C-flute: the most common, balancing cost and strength.

- ईटी & F-flutes: microflutes, used in cosmetics, इलेक्ट्रानिक्स, and luxury rigid packaging.

एसmithers research shows microflute use is growing thanks to e-commerce and “shelf-ready” packaging. Luxury chocolate brands in Europe now prefer microflute rigid sleeves to replace plastic trays.

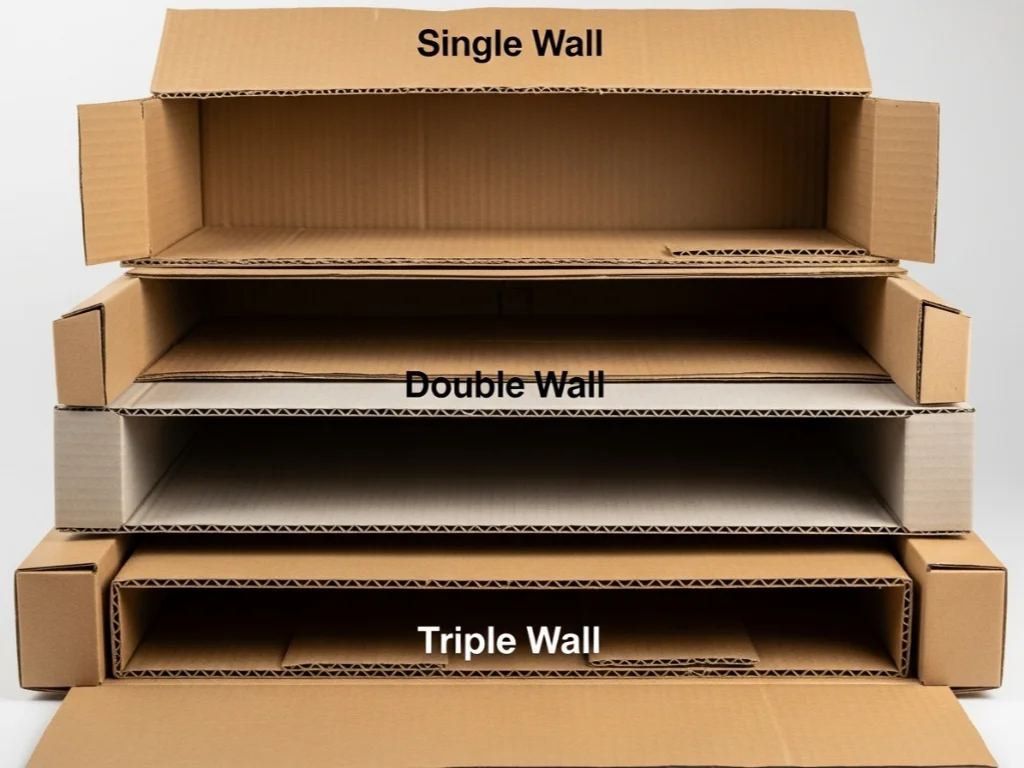

Building Layers From Single to Triple Wall

Depending on what needs shipping, corrugated board is layered differently:

- Single wall (two liners + one flute): the everyday shipping box.

- Double wall: two flutes + three liners, popular in long-distance export.

- Triple wall: heavy-duty, often replacing wood in machinery or bulk food shipments.

पर PACKCCP, our European clients in fashion and lifestyle industries often choose double wall structures for e-commerce. It’s a middle ground: lighter than wood, but strong enough to cross continents without collapse.

For more on how structural design is developed, see our guide: पैकेजिंग में डाइलाइन क्या है??.

From Flat Sheets to Finished Boxes

Once the board is ready, the transformation into boxes begins:

- Cutting & slotting: sheets are trimmed and creased for folding.

- छपाई: designs are applied—anything from handling symbols to full-colour logos. ए McKinsey report noted that 72% of consumers link packaging design directly to product quality.

- Folding & gluing: flat blanks are assembled, stacked, and shipped to clients.

पैकसीसीपी पर, we add luxury finishes—foil stamping, उभार, or even rigid box conversion—helping clients use corrugated packaging not just as a shipping tool, but as a branding asset.

Recycling Closing the Loop

Corrugated is one of the most recycled packaging materials in the world.

- In the U.S., it reached a recovery rate of 93.6% in 2022 (EPA).

- Recycling reduces virgin fibre demand and lowers CO₂ emissions.

- NielsenIQ reports 78% of consumers are willing to switch brands if sustainable packaging is offered.

पर PACKCCP, this translates into FSC-certified papers, eco-coatings, and recyclable adhesives. For premium markets in Australia and Northern Europe, these certifications aren’t just nice-to-have—they’re often mandatory in supplier tenders.

अंतिम विचार

From pine forest fibres to a finished export carton, corrugated cardboard is a story of engineering and renewal. Each flute, adhesive bond, and cut line determines whether the box can carry a load safely—or elevate a brand in the eyes of its customers.

For B2B buyers, the choice of supplier makes all the difference. पर PACKCCP, we don’t just manufacture boxes—we engineer custom corrugated and rigid solutions that combine durability, डिज़ाइन, and sustainability for markets across Australia, यूरोप, और उत्तरी अमेरिका.

FAQs

1. Why is corrugated cardboard stronger than regular paperboard?

Because of its fluted inner layer, which acts like a spring to absorb shocks.

2. Can corrugated packaging be used for luxury products?

Yes—when combined with high-end finishes like embossing or foil, corrugated can look premium while staying eco-friendly.

3. Is corrugated always recyclable?

Nearly all corrugated is recyclable, provided coatings or laminations are eco-compatible.

4. What flute type is best for e-commerce packaging?

C-flute is most common, but double-wall E+C flutes are preferred for fragile or high-value shipments.

5. Why work with packccp for corrugated packaging?

Because we specialise in B2B custom designs, blending strength, ब्रांडिंग, and eco certifications to meet international buyer demands.