Desde o envio de seus pedidos on-line até a proteção de eletrônicos frágeis, desde o armazenamento de utensílios domésticos até a exibição de produtos nas lojas – por que há caixas de papelão ondulado em todas as embalagens?? A força deles, acessibilidade, e a compatibilidade ecológica fazem deles a escolha preferida. Este artigo explora como eles são feitos, seus benefícios em logística e branding, usos específicos da indústria, e conformidade com padrões globais, ajudando você a selecionar embalagens que sejam práticas e confiáveis.

O que são caixas de papelão ondulado e como são feitas?

As caixas de papelão ondulado são feitas de papelão ondulado, que imprensa uma ou mais camadas caneladas entre placas de revestimento planas. Esta estrutura inteligente em camadas torna as caixas fortes e leves, para que possam proteger os produtos durante o transporte, empilhe ordenadamente no armazenamento, e ainda fica bem para exibição no varejo.

O processo por trás deles é surpreendentemente preciso. O papelão é feito primeiro de papel kraft ou reciclado. O meio canelado é então moldado através de rolos corrugados para adicionar resistência. Estas folhas caneladas são coladas entre os revestimentos para formar uma parede única, parede dupla, ou mesmo placas de parede tripla. Finalmente, as tábuas são cortadas, vincado, e impresso para atender formas personalizadas e necessidades de marca.

Se você quiser saber mais, clique aqui para ver a íntegra processo de fabricação de caixas de papelão ondulado.

Eficiência de custos

As embalagens de papelão ondulado continuam sendo a escolha preferida de muitas empresas graças à sua relação custo-benefício. Comparado com caixas de plástico ou caixas de madeira, materiais corrugados são baratos, leve, e reciclável, ajudando a reduzir custos logísticos iniciais e de longo prazo.

- Design leve

O papelão ondulado oferece alta resistência com baixo peso, reduzindo os custos de frete para transporte aéreo e terrestre. Vendedores de comércio eletrônico, por exemplo, economize na entrega final, mantendo os produtos frágeis bem protegidos.

- Economia de espaço

As caixas são enviadas e armazenadas planas, otimizando o espaço do armazém e simplificando a distribuição. Este recurso suporta paletização eficiente e linhas de embalagem automatizadas, permitindo que as empresas minimizem os custos de armazenamento e melhorem o rendimento em centros de distribuição como os operados pela Amazon.

- Produção escalável

As embalagens de papelão ondulado podem ser fabricadas rapidamente em formatos padronizados ou personalizados. Linhas de conversão de alta velocidade reduzem custos por unidade para grandes campanhas sazonais, como lançamentos de produtos eletrônicos de consumo ou promoções de feriados, sem comprometer o desempenho estrutural.

- Redução de danos

Opções de múltiplas paredes e perfis variados de canais proporcionam resistência superior ao impacto e à compressão, reduzindo danos de trânsito e devoluções relacionadas. Isto não só protege as margens, mas também preserva a satisfação do cliente e a confiança na marca em ambientes de varejo competitivos..

- Adaptabilidade da cadeia de suprimentos (fator adicional)

As caixas de papelão ondulado integram-se perfeitamente aos sistemas logísticos modernos, desde classificadores automatizados até rastreamento habilitado para IoT. Dimensões padrão e compatibilidade com códigos de barras simplificam o gerenciamento de estoque e o cross-docking, reduzindo ainda mais custos operacionais e desperdícios.

Para setores como comércio eletrônico e FMCG, a eficiência da embalagem impacta diretamente as margens de lucro. Estudos mostram que soluções otimizadas de papelão ondulado podem reduzir custos de embalagem em 15–25%, muitas vezes superando os investimentos iniciais em design e personalização.

Sustentabilidade é importante

Sustentabilidade é um fator chave na escolha da embalagem. As caixas de papelão ondulado são amplamente reconhecidas como uma opção ecologicamente correta, atendendo às expectativas do consumidor e aos requisitos regulatórios.

- Reciclabilidade

A maioria das caixas de papelão ondulado contém 70–100% de fibra reciclada e pode ser reciclada até sete vezes, reduzindo a demanda por matérias-primas e mantendo os resíduos fora dos aterros.

- Fontes renováveis

Os principais fabricantes usam o Forest Stewardship Council (FSC®) papel certificado, garantir que as fibras provêm de florestas geridas de forma responsável e apoiar os objetivos de sustentabilidade empresarial.

- Menor pegada de carbono

Seu design leve reduz o consumo de combustível durante o transporte, ajudando as empresas a reduzir as emissões de carbono – um fator crucial para cumprir o Escopo 3 alvos.

- Conformidade com padrões globais

As caixas de papelão ondulado atendem aos padrões globais, como a Diretiva de Embalagens e Resíduos de Embalagens da UE e a Diretiva dos EUA. Diretrizes da EPA, tornando o transporte internacional mais simples e menos dispendioso.

Este forte perfil de sustentabilidade também explica porque o papelão ondulado é usado em embalagens de alimentos, como caixas de pizza, graças à sua retenção de calor, biodegradabilidade, e conformidade com os padrões de segurança em contato com alimentos (Por exemplo, FDA 21 CFR).

Personalização e branding

As embalagens de papelão ondulado fazem mais do que proteger os produtos – elas também servem como uma poderosa ferramenta de branding. Com impressão moderna e design estrutural, as empresas podem transformar a embalagem em um ativo de marketing que melhora a experiência do cliente.

- Projeto estrutural

Tamanhos personalizados, janelas cortadas, e inserções ajudam os produtos a permanecerem seguros e parecerem atraentes quando retirados da caixa, especialmente para eletrônicos e itens premium.

- Tecnologias de impressão

Flexografia, digital, e a impressão litolaminada permitem logotipos de alta resolução, gráficos, e códigos QR, aumentando o reconhecimento da marca e criando momentos memoráveis de unboxing para e-commerce ou caixas de assinatura.

- Revestimentos especiais

Camadas resistentes à umidade ou à prova de gordura preservam a integridade da embalagem e a segurança do produto, fundamental para a alimentação, farmacêutico, e itens sensíveis.

- Embalagem pronta para varejo

Caixas projetadas para exibição direta nas prateleiras reduzem o trabalho de reabastecimento e melhoram o visual merchandising, amplamente utilizado em supermercados e grandes varejistas de alimentos e produtos de higiene pessoal.

- Recursos de segurança

Selos invioláveis ou abas reforçadas impedem o acesso não autorizado e protegem itens de alto valor, como cosméticos ou pequenos eletrônicos.

Caixas de papelão ondulado protegem os produtos e melhoram a experiência da marca, oferecendo vantagens claras em relação às caixas simples ou embalagens genéricas.

Tipos de caixas de papelão ondulado

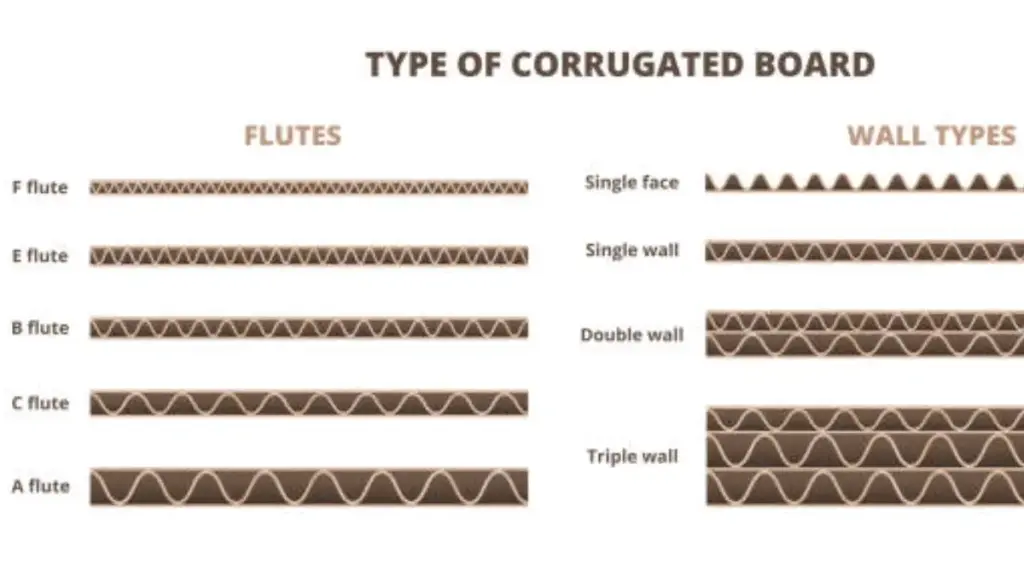

As caixas de papelão ondulado variam na construção da parede – parede única, parede dupla, e parede tripla - e perfis de flauta como um, B, C, E, e flautas F. Cada combinação oferece benefícios distintos: A flauta fornece amortecimento superior para produtos frágeis; A flauta B oferece resistência de empilhamento para displays de varejo; E- e flautas F são mais finas, adequado para pequenos bens de consumo e impressão de alta qualidade.

Do ponto de vista do desempenho físico, papelão ondulado fornece proteção contra impactos, resistência à compressão, e absorção de choque, que são essenciais para o transporte marítimo de longa distância. Isso explica por que usar caixas de papelão ondulado para embalagens em indústrias onde a redução das taxas de danos reduz diretamente os custos e aumenta a satisfação do cliente.

Aplicações Industriais de caixas de papelão ondulado

Pense em quão diferente é um frágil vaso de vidro, uma caixa de pizza, ou uma remessa de livros precisa ser embalada – cada uma exige um tipo específico de caixa de papelão ondulado que equilibre a proteção, custo, e apresentação.

| Indústria | Tipo de caixa recomendado | Benefícios |

| Comércio eletrônico (Amazônia, Fornecedores do Shopify) | Parede simples ou dupla com canal B/C | Equilibra proteção e peso; facilmente marcado para experiência de unboxing |

| Comida e bebida (Pizza, Produzir) | Flauta E ou flauta B de parede única | Retenção de calor, respirabilidade, eficiência de custos; responde por que o papelão ondulado é usado em caixas de pizza |

| Eletrônica | Parede dupla com revestimentos antiestáticos | Proteção contra impactos e vibrações; evita danos eletrostáticos |

| Bens Industriais/Pesados | Parede tripla com combinação de flauta A/B | Alta resistência à compressão para máquinas ou componentes automotivos |

Padrões e tendências futuras em embalagens de papelão ondulado

Quando se trata de embalagem, não se trata apenas da caixa em si – os padrões globais garantem que ela seja segura, durável, e sustentável. Da ISO 18604 sobre o impacto ambiental nos testes ISTA para desempenho de trânsito, esses benchmarks dão às empresas e aos parceiros da cadeia de suprimentos confiança em qualidade consistente.

- Embalagem inteligente: Integração de códigos QR ou RFID para rastreabilidade e gestão de inventário.

- Inovação leve: Razões resistência-peso aprimoradas usando designs avançados de caneluras.

- Foco na economia circular: Maior ênfase na reciclagem em circuito fechado e revestimentos biodegradáveis.

- Compatibilidade de automação: Dimensões de caixa padronizadas projetadas para linhas de embalagem robóticas.

À medida que as tendências de embalagens evoluem, conhecer esses desenvolvimentos permite que as empresas permaneçam à frente e reforça por que as caixas de papelão ondulado continuam sendo uma escolha inteligente em mercados em constante mudança.

Conclusão

Caixas de papelão ondulado combinam proteção, eficiência de custos, e sustentabilidade, tornando-os uma escolha de embalagem essencial para indústrias como a alimentícia, comércio eletrônico, e eletrônica.

Para empresas que procuram um parceiro confiável, PacoteCCP se destaca com produção totalmente interna, Certificações FSC/BSCI/CE/ROHS, e fortes capacidades de personalização em design estrutural e branding. Seu processo totalmente ecológico garante conformidade e aceitação no mercado global.

Contate-nos hoje para explorar sob medida embalagem de papelão ondulado soluções que melhoram o desempenho e o valor da marca.