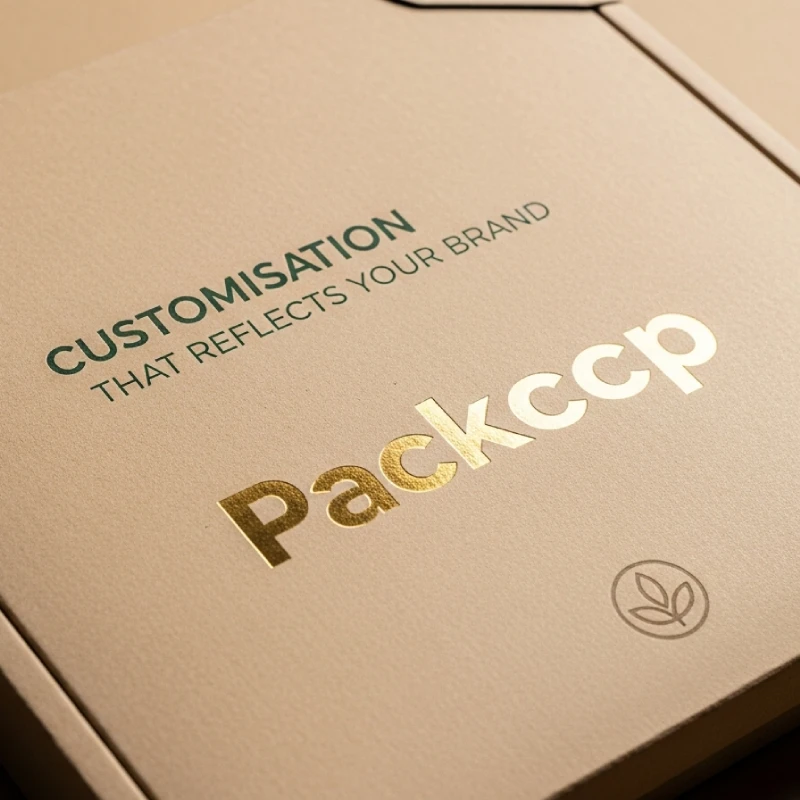

Des boîtes rigides avec une finition luxueuse qui augmente la valeur perçue

Idéal pour protéger les produits fragiles ou haut de gamme lors du transport ou de l'exposition.

Convient aux bijoux, produits de beauté, électronique, et emballage cadeau.

La structure robuste garantit un aspect épuré et une meilleure expérience de déballage.

Vous pouvez personnaliser votre taille d'emballage pour bien s'adapter à votre produit.

Toute taille, Tous les conceptions.

Heiderberg CX104 6 couleurs Machine d'impression compensée

Komori Lithrone GX40 Advance Machine d'impression UV compensée

Eco-Friendly & Sustainability

Émissions de COV inférieures

Couleurs vibrantes

Écologique ,recycable, , Biodégradable , Le papier certifié FSC est disponible

Vous êtes libre de choisir vos couleurs de conception, y compris CMYK, Pantone, couleurs métalliques, et blanc.

La qualité d'impression est affectée par la planéité du papier, absorption de l'humidité, lisse de surface, Processus de qualité et d'impression de l'encre et autres aspects. Sélection d'équipements et processus d'impression appropriés, Un contrôle raisonnable de l'environnement d'impression et des conditions de stockage du papier peut considérablement améliorer la qualité de l'impression.

Sélectionnez du papier et des revêtements qui répondent aux normes pour les matériaux de contact alimentaire, Évitez l'utilisation de produits chimiques contenant des métaux lourds et d'autres substances dangereuses, et contrôler strictement l'environnement de production et les processus pour s'assurer que les emballages en papier ne contaminent pas les aliments pendant la fabrication, stockage et utilisation.

Différentes formes ondulées sont sélectionnées en fonction du poids, Conditions de forme et de transport du produit. Une flûte convient pour emballer des objets lourds qui nécessitent un soutien solide, La flûte b convient plus pour l'emballage de petites matières premières, La flûte C convient à un large éventail d'applications, en tenant compte à la fois d'amorti et de soutien, et la flûte E et F convient à l'emballage de produits fins haut de gamme.

Notre production d'emballages est en Chine, L'emplacement spécifique dépend des différents types d'emballage.

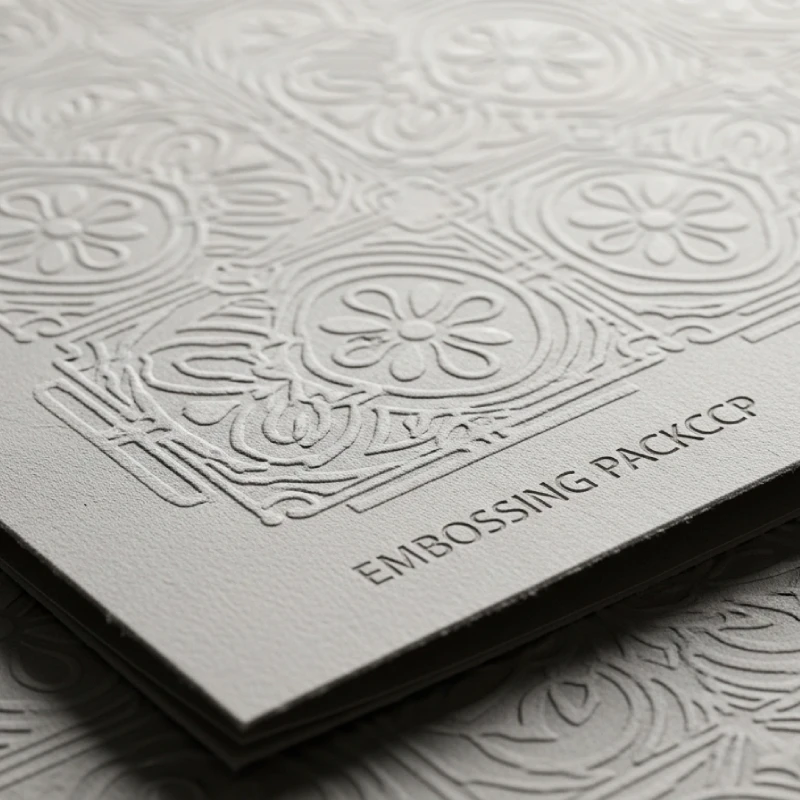

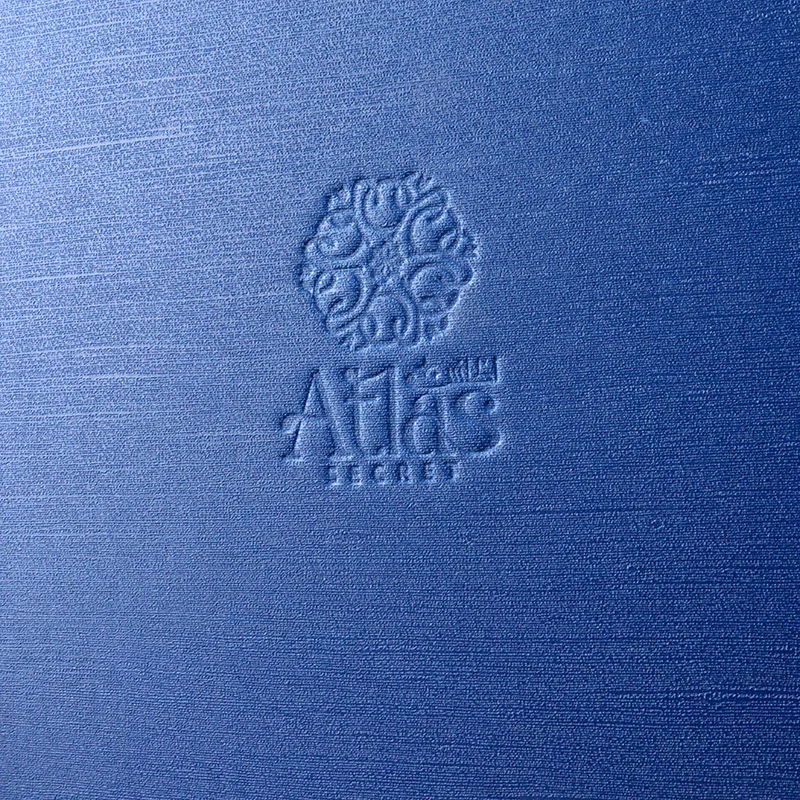

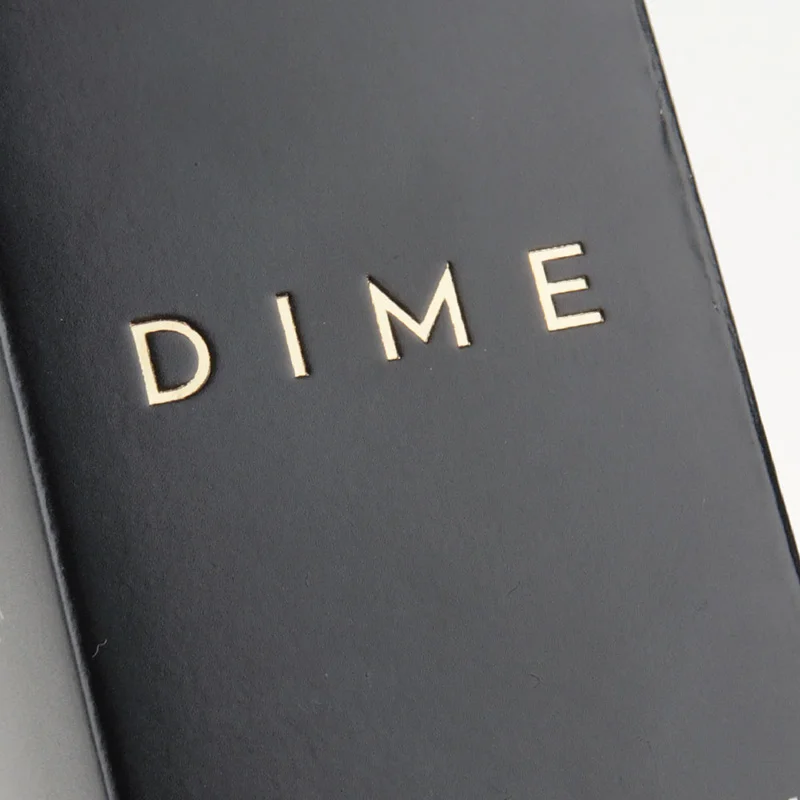

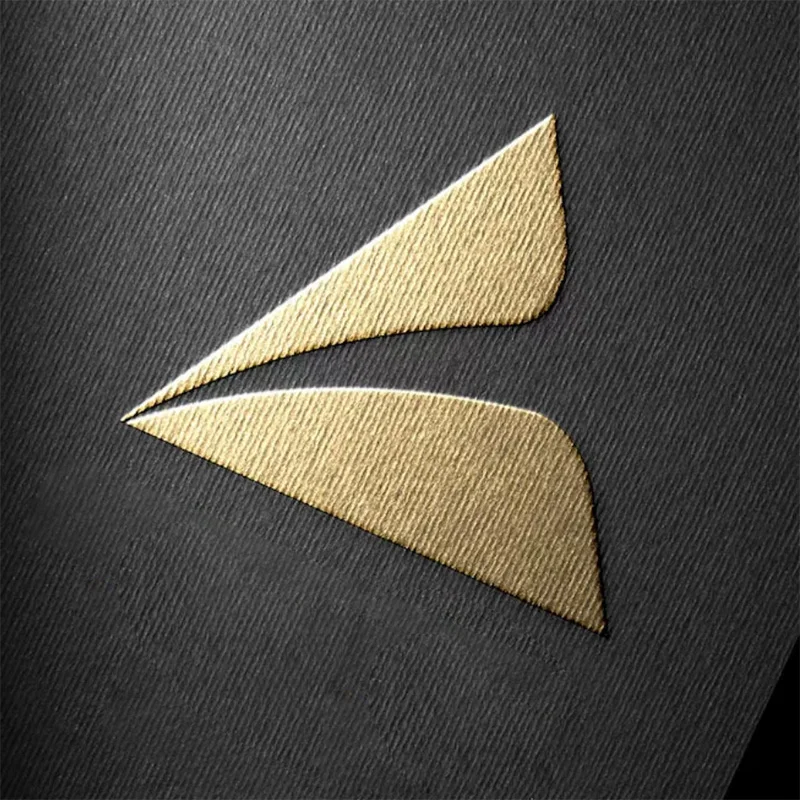

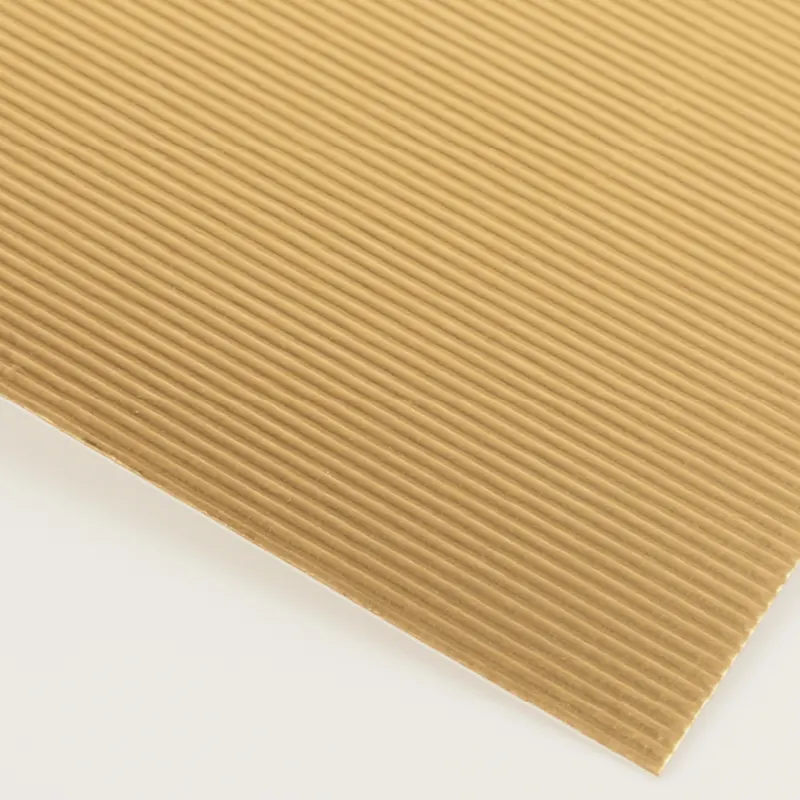

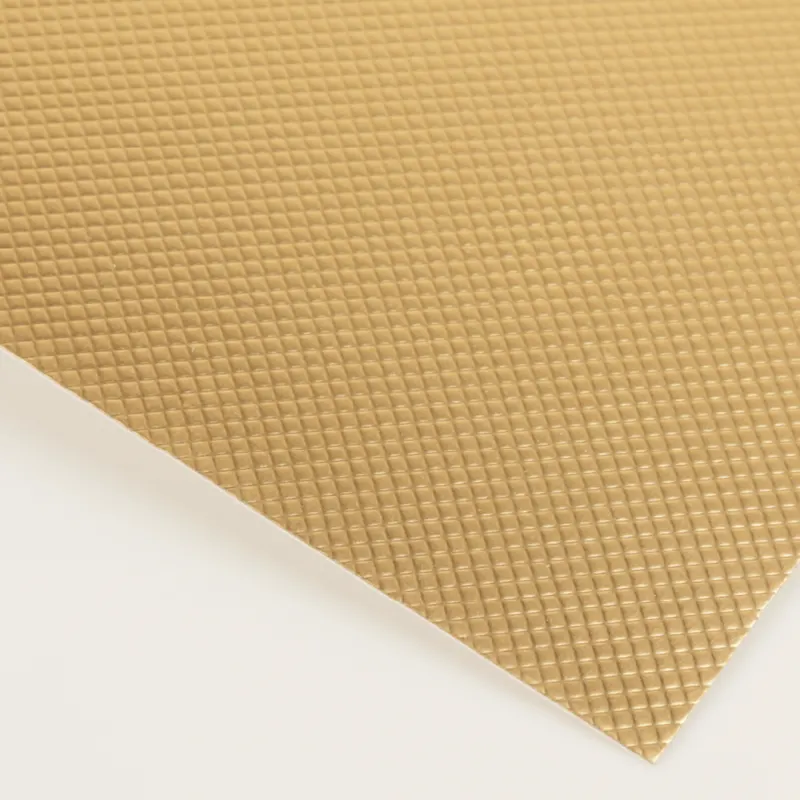

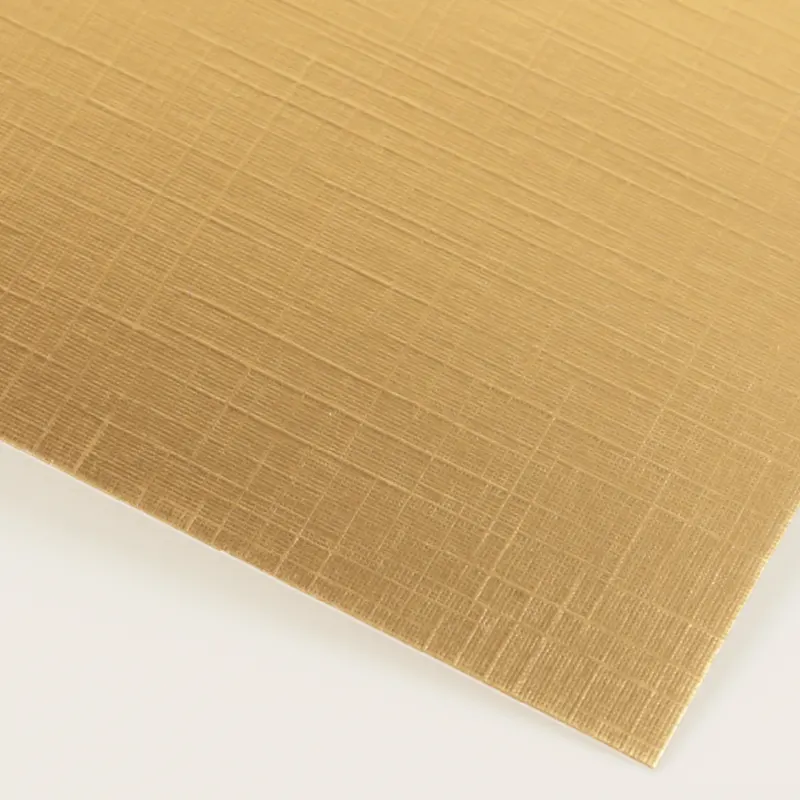

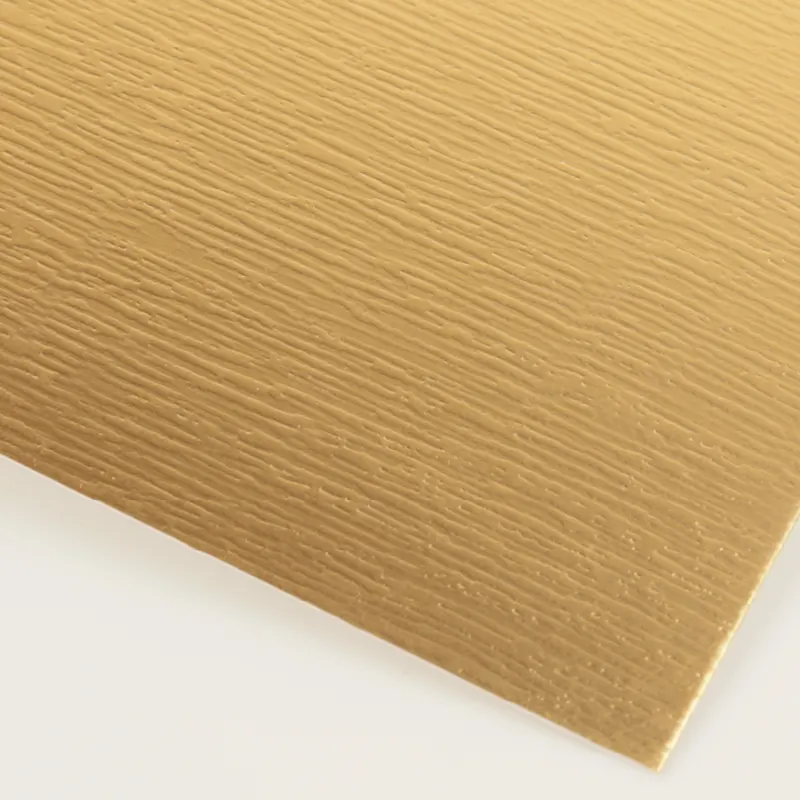

Diverses finances ont des caractéristiques différentes telles que la brillance, Mat, Toucher doux, Texture

Faites en sorte que le logo de votre marque soit exceptionnel, comme l'effet métallique, Soulevé, Brillant concave ou partiel

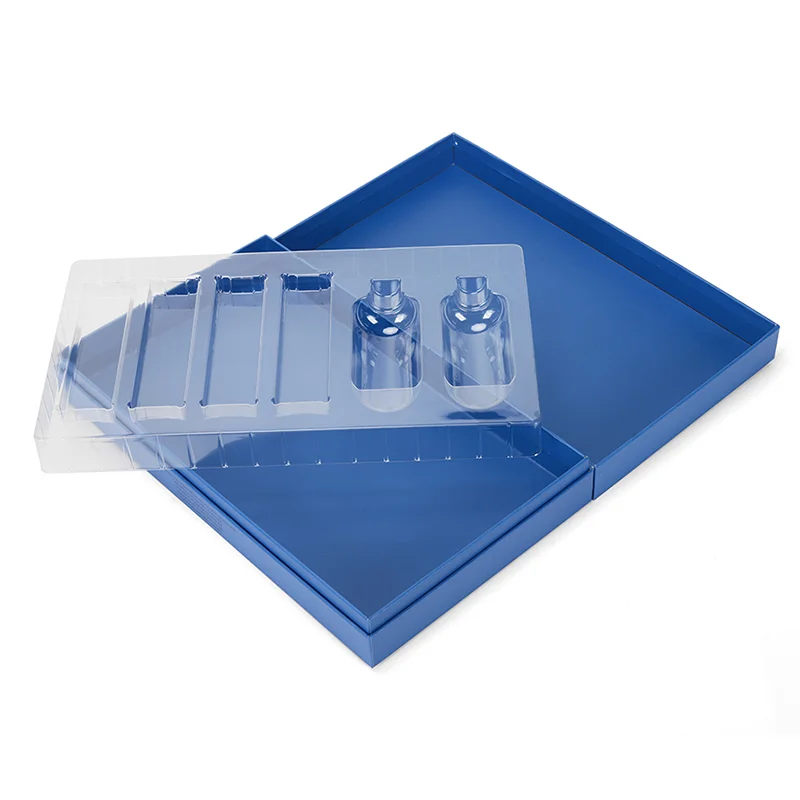

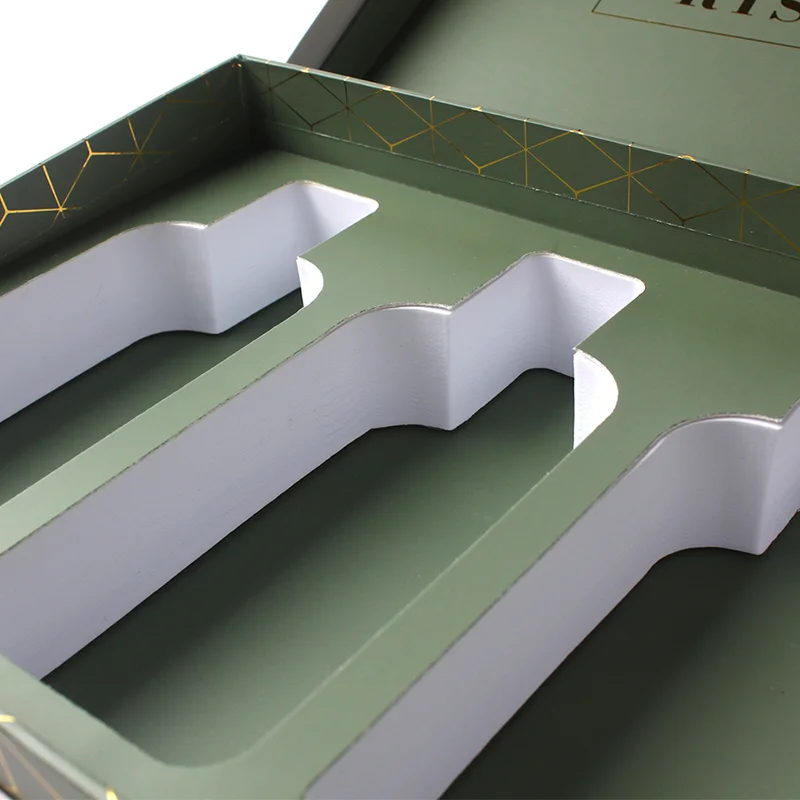

Choisissez une bonne boîte inserts pour ajuster sur mesure et protéger tous vos produits pour vous assurer qu'ils restent en toute sécurité, ou utiliser l'amorti et empêche les mouvements ou les dommages pendant le transport, Nous avons généralement conçu pour une insertion et une suppression simples, faciliter un emballage efficace pour un assemblage facile

Bienvenue pour utiliser les services PackCCP, Nous sommes le fabricant chinois dans les activités d'impression et d'emballage pour plus 30 années. Vous trouverez un emploi facile de communiquer avec nos ventes expérimentées avec une compréhension complète de vos besoins d'emballage. Notre équipe vous soutiendra pleinement dans la conception, échantillon ,production et expédition.

Vous pouvez sélectionner la diéline dans nos vastes options ou nous dire les produits dont vous avez besoin pour emballer et nous pouvons vous donner des solutions d'emballage.

Après avoir confirmé le style et la taille de la boîte, matériel, Quantité Nos ventes offriront un devis.

Nous pouvons fournir une diéline personnalisée à votre concepteur pour créer l'œuvre d'art, Après avoir confirmé l'œuvre d'art, Notre équipe d'Engeering vous aidera dans l'échantillon en fonction de votre conception personnalisée ,Matériau de taille et de production

Nous vous enverrons un échantillon par express pour confirmer la qualité de l'échantillon, Si la commande est confirmée, Nous organiserons un IP pour que vous puissiez organiser le dépôt.

Après avoir reçu votre dépôt, Nous organiserons immédiatement des échantillons et des produits finaux.

Vous pouvez utiliser votre propre transmit, soit notre transfert pour expédier les marchandises.

Non, c'est exw, GOUSSET, Cif, DDU ou DDP ou expédition à votre fournisseur pour assembler les produits, Nous sommes expérimentés dans tout .

La qualité d'impression est affectée par la planéité du papier, absorption de l'humidité, lisse de surface, Processus de qualité et d'impression de l'encre et autres aspects. Sélection d'équipements et processus d'impression appropriés, Un contrôle raisonnable de l'environnement d'impression et des conditions de stockage du papier peut considérablement améliorer la qualité de l'impression.

Sélectionnez du papier et des revêtements qui répondent aux normes pour les matériaux de contact alimentaire, Évitez l'utilisation de produits chimiques contenant des métaux lourds et d'autres substances dangereuses, et contrôler strictement l'environnement de production et les processus pour s'assurer que les emballages en papier ne contaminent pas les aliments pendant la fabrication, stockage et utilisation.

Différentes formes ondulées sont sélectionnées en fonction du poids, Conditions de forme et de transport du produit. Une flûte convient pour emballer des objets lourds qui nécessitent un soutien solide, La flûte b convient plus pour l'emballage de petites matières premières, La flûte C convient à un large éventail d'applications, en tenant compte à la fois d'amorti et de soutien, et la flûte E et F convient à l'emballage de produits fins haut de gamme.

Notre production d'emballages est en Chine, L'emplacement spécifique dépend des différents types d'emballage.

*Toutes vos informations sont respectées & protégé dans Packccp.