Vous êtes-vous déjà demandé pourquoi certains sacs en papier semblent plus solides et plus fiables que d'autres ?? En production en vrac, la qualité de vos sacs en papier va au-delà de l'apparence : il s'agit de garantir qu'ils fonctionnent comme prévu dans des conditions réelles. Que vous emballiez des produits pour la vente au détail ou que vous créiez des solutions personnalisées, comprendre les facteurs clés qui ont un impact sur la qualité vous aidera à faire les bons choix.

Ce guide vous explique tout ce que vous devez savoir, de la sélection des bons matériaux aux inspections finales, t'aider choisissez des sacs en papier à la fois fonctionnels et conformes à la marque. À la fin, vous saurez exactement comment garantir la meilleure qualité pour votre entreprise.

Choisir le bon papier pour la production

Le papier utilisé dans la fabrication des sacs en papier constitue la base du produit. Tous les articles ne sont pas créés égaux, et sélectionner le bon type de papier est essentiel pour la durabilité, apparence, et fonctionnalité du sac.

Il y a quelques principaux types de matériaux de papier couramment utilisé dans la production de sacs en papier: papier kraft, papier recyclé, et papier vierge. Chaque type a son propre ensemble d'avantages et d'inconvénients en fonction de l'usage des sacs..

- Papier kraft: Connu pour sa solidité et son aspect rustique, Le papier kraft est l'un des matériaux les plus couramment utilisés dans la production de sacs en papier.. Il n'est pas blanchi et est souvent considéré comme l'option la plus écologique en raison de sa nature biodégradable..

- Papier recyclé: Pour les entreprises axées sur le développement durable, le papier recyclé est un excellent choix. Il est fabriqué à partir de déchets post-consommation, contribuer à réduire l’impact environnemental. Cependant, il est important de noter que le papier recyclé peut être légèrement moins durable que le papier kraft vierge., en fonction du processus de recyclage.

- Papier vierge: Ce type de papier est fabriqué à partir de pâte fraîche et est généralement plus résistant et plus durable que le papier recyclé.. Il est idéal pour les sacs qui transportent des objets plus lourds ou qui résistent à une manipulation brutale.

En choisissant le bon papier, vous souhaiterez équilibrer les considérations environnementales et la fonctionnalité. Par exemple, si vos sacs doivent transporter des objets lourds, le papier vierge pourrait être votre meilleur choix, tandis que si la durabilité est une priorité absolue, le papier recyclé ou kraft pourrait bien fonctionner.

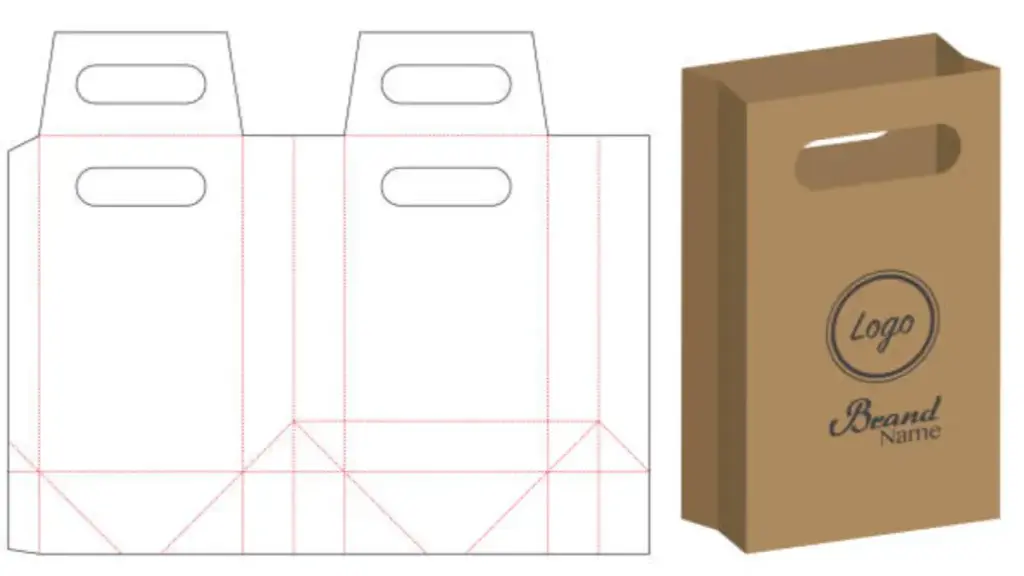

Dimensions et spécifications clés

Suivant, vous devez vous renseigner sur les dimensions et les spécifications des sacs en papier. Ces facteurs auront un impact direct sur la résistance du sac, capacité, et fonctionnalité.

- Taille du sac: Les sacs en papier sont disponibles en différentes tailles, des petits sacs cadeaux aux grands sacs d'épicerie. Les tailles les plus courantes sont souvent appelées #1, #2, et #3, avec #1 étant un sac de petite taille pour des bijoux ou de petits objets et #3 étant un grand sac pour les produits plus volumineux.

- Largeur du gousset: Le soufflet est la partie extensible du sac qui lui permet de s'ouvrir plus largement. Il est généralement situé sur les côtés ou en bas. La largeur du soufflet affecte la capacité du sac à transporter plus d'articles. Un soufflet plus profond signifie que le sac peut contenir davantage sans compromettre sa résistance..

- Type de poignée: Le type de poignée utilisée dans le sac, qu'il s'agisse d'une poignée torsadée en papier, coton, ou en plastique – joue également un rôle dans la fonctionnalité du sac. La solidité de la poignée doit être prise en compte parallèlement à la capacité de poids du sac..

Des mesures précises garantissent que vos sacs en papier peuvent supporter la charge prévue sans compromettre la résistance. PackCCP propose des experts services de personnalisation pour garantir que vos sacs répondent exactement à vos spécifications.

Qualité de surface et durabilité

La qualité de la surface n’est pas seulement une question d’apparence; cela a un impact sur l'expérience tactile et la durabilité du sac en papier. Un papier de mauvaise qualité présentant des défauts visibles peut réduire considérablement l'attrait général du produit..

- Douceur: Plus la surface du papier est lisse, plus il est probable qu'il offre un look professionnel et haut de gamme. Cependant, des surfaces plus lisses peuvent également rendre le papier plus susceptible de se déchirer, donc l'équilibre est la clé.

- Finition: Différentes finitions, comme mat ou brillant, peut changer la texture et la résistance du papier. Les finitions mates donnent souvent un aspect plus naturel, tandis que les finitions brillantes peuvent être utilisées pour les sacs haut de gamme qui nécessitent un éclat supplémentaire pour le marquage..

- Résistance à la traction: Cela fait référence à la force que le papier peut supporter avant de se casser.. Un papier plus résistant contribuera à garantir que vos sacs résistent lorsque vous transportez des objets lourds ou pendant le transport..

Normes d'impression et de marque

Pour les entreprises qui cherchent à faire forte impression, la qualité d'impression et le marquage sur les sacs en papier peuvent faire toute la différence. L'impression de haute qualité contribue à rehausser l'apparence générale du sac, tandis qu'une mauvaise impression peut nuire à sa valeur perçue.

- Qualité de l'encre: Assurez-vous toujours que l’encre utilisée pour l’impression est durable et résistante à la décoloration.. Les encres à base d'eau sont couramment utilisées dans les emballages écologiques, tandis que les encres à base d'huile peuvent être plus durables mais moins respectueuses de l'environnement.

- Clarté d'impression: L'impression doit être claire et nette, sans saignement ni bavure. Ceci est particulièrement important pour les logos et les noms de marque, qui doit être facilement reconnaissable et lisible.

- Considérations de conception: Lors de la conception de sacs en papier, considérer toute la surface. Un design qui recouvre le devant et le dos du sac peut améliorer son attrait visuel, mais il doit également être équilibré avec les aspects fonctionnels comme le placement des poignées ou des goussets..

La qualité d’impression de vos sacs en papier doit refléter le professionnalisme de votre marque. Une impression de haute qualité améliorera non seulement l'apparence de vos sacs, mais renforcera également l'identité de votre marque..

Assurer des coutures et des renforts solides

Les sacs en papier sont aussi solides que leur point le plus faible, et cela réside souvent dans les coutures. Qu'ils soient collés ou cousus, le renforcement des coutures garantit que le sac maintient sa durabilité sous pression.

- Coutures latérales: Ces coutures doivent être suffisamment solides pour supporter le poids du contenu. Certains fabricants utilisez des coutures doubles ou un collage renforcé pour plus de solidité, ce qui est essentiel pour les sacs lourds.

- Renforts inférieurs: De nombreux sacs en papier, surtout les plus grands, bénéficier de renforts de fond. Cela pourrait inclure des couches supplémentaires de papier ou un pliage pour créer une base plus solide.. Le fond du sac doit également être solidement collé pour éviter que les objets ne tombent..

- Renforts de poignée: Si le sac a des poignées, assurez-vous qu’ils sont renforcés avec des couches supplémentaires de papier ou de coton, en particulier pour les sacs qui transporteront des objets plus lourds.

Les coutures et les renforts sont souvent le premier point de rupture d'un sac en papier, il est donc essentiel de prêter une attention particulière à leur qualité. En vous assurant qu'ils sont solidement fixés et renforcés, vos sacs ne s'effondreront pas sous la pression..

Test de résistance et de capacité de charge

La réalisation de tests de résistance avant la production en vrac confirme que vos sacs en papier peuvent supporter le poids et l'utilisation prévus., avec test de capacité de charge garantissant la fiabilité.

- Tests de charge: Testez les sacs avec une variété de poids et de conditions de chargement. Un sac en papier bien fait ne doit pas se déchirer ou se déformer lorsqu'il est rempli avec son poids maximum prévu..

- Essais de traction et d'éclatement: Ces tests mesurent la résistance du papier lorsqu’il est soumis à des contraintes, simuler les performances du sac dans des conditions réelles.

- Tests de durabilité: Pensez à soumettre les sacs à des conditions qui imitent leur utilisation réelle, comme l'exposition à l'humidité, stress lié au poids, ou une manipulation brutale.

Effectuer des tests rigoureux garantit que vos sacs en papier répondent aux normes de résistance et de fonctionnalité requises.. Ces tests doivent être effectués sur des échantillons aléatoires tout au long de la production pour maintenir la cohérence.

Contrôle qualité final et emballage

Après la production, une finale contrôle de qualité l'inspection garantit que tous les défauts sont identifiés avant d'atteindre le client, couvrant tout, de la qualité d'impression à la fonctionnalité des coutures et des poignées. Ce processus implique de tout vérifier, de la qualité d'impression à la fonctionnalité des coutures et des poignées..

- Inspections visuelles: Inspecter les sacs pour vérifier la cohérence des couleurs, erreurs d'impression, et tout signe de défauts comme les rides, plis, ou déchirer.

- Mesures finales: Assurez-vous que chaque sac répond aux spécifications de taille convenues. Même de légères variations de taille peuvent entraîner des sacs inutilisables ou mal ajustés..

- Conditionnement: Un emballage approprié évite les dommages pendant le transport, s'assurer que les sacs arrivent en parfait état. Assurez-vous que les sacs sont soigneusement emballés, avec une protection suffisante contre l’humidité ou les dommages physiques.

Une inspection finale approfondie est la dernière ligne de défense contre les sacs en papier de mauvaise qualité.. En effectuant une inspection détaillée, vous pouvez détecter tous les problèmes avant qu'ils n'atteignent vos clients, garantir que seuls les sacs de la meilleure qualité arrivent sur le marché.

Conclusion

En conclusion, garantir la qualité des sacs en papier passe par la sélection du bon papier, dimensions précises, coutures solides, et une impression fiable. Des tests rigoureux et des inspections finales garantissent que vos sacs sont durables et fonctionnels pour une utilisation réelle.

Avec durabilité devenant de plus en plus important, Packccp offre une haute qualité, des sacs en papier écologiques adaptés aux besoins de votre marque. Faites-nous confiance pour fournir des produits durables, des solutions durables qui valorisent vos emballages. Prêt à rehausser votre emballage? Contactez PackCCP aujourd’hui pour créer les sacs en papier parfaits pour votre entreprise.