This article explains flute types in corrugated boxes—A, B, C, E, and F flutes—covering their thickness, compression strength, and structural performance. It also examines single‑, double‑, and triple‑wall combinations, practical applications, and key selection considerations. The guide aims to help packaging engineers and procurement teams choose the most suitable types of flutes in corrugated box designs.

What Are Flute Types in Corrugated Boxes and Why They Matter in Packaging?

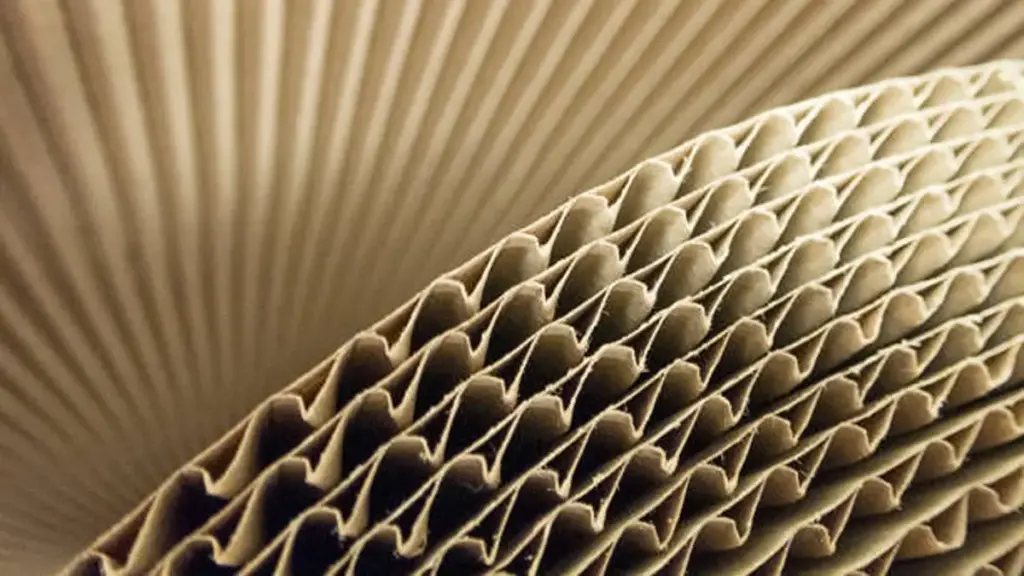

Flutes are the wave‑shaped mediums placed between linerboards in corrugated packaging. These structural profiles create air pockets that enhance rigidity and cushioning without adding excessive weight. According to the Fibre Box Association (FBA), flute size directly influences compression strength and surface smoothness, which are critical for both product protection and print quality.

Corrugated boards with flutes are widely used in shipping and retail because they combine strength with lightweight efficiency. Their design reduces material use while maintaining durability, supporting cost‑effective logistics and sustainable packaging goals. Industry standards such as ISO 3034 regulate measurement of corrugated board thickness and strength, ensuring consistent performance across global supply chains.

Detailed Comparison of A, B, C, E, and F Flute Types

A Flute

A flute is the thickest among corrugated flutes, measuring around 4.7–5.0 mm with about 33 flutes per foot. Its larger waves provide superior cushioning and stacking strength, making it suitable for fragile or heavy products such as glassware and industrial equipment. This type is commonly used where maximum protection is required during long-distance transport.

B Flute

B flute is thinner at approximately 2.5–3.0 mm and features about 47 flutes per foot. It offers high resistance to crushing and creates a smooth surface for printing. This makes it popular for canned goods, beverage trays, and retail displays requiring both rigidity and good graphics presentation.

C Flute

C flute measures roughly 3.5–4.0 mm thick with 39 flutes per foot. It strikes a balance between cushioning and compression strength, becoming the most widely used option for general shipping cartons. Many standard e-commerce boxes and consumer goods packaging rely on C flute for versatile performance.

E Flute

E flute is a micro-flute option with a thickness of about 1.0–1.8 mm and around 90 flutes per foot. Its fine structure provides a flat surface for high-quality printing, making it ideal for retail packaging and smaller product boxes where design presentation is critical.

F Flute

F flute is even thinner at approximately 0.8–1.2 mm, featuring over 120 flutes per foot. It is commonly chosen for luxury packaging, cosmetics, and small electronics that demand detailed print quality and a premium appearance, while still offering moderate protective qualities.

Each flute type serves distinct packaging purposes, balancing protection, printability, and material efficiency. Interestingly, there is no widely recognized D flute because its specifications overlap with C and E flutes, offering no significant functional advantage or cost benefit compared to these more standardized options.

Single‑Wall, Double‑Wall, and Triple‑Wall Flute Combinations Explained

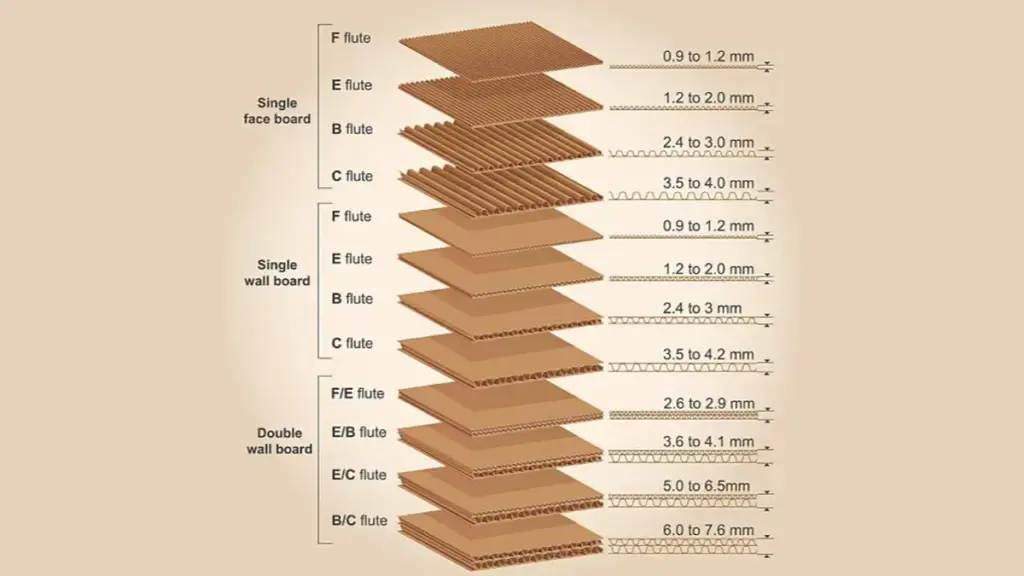

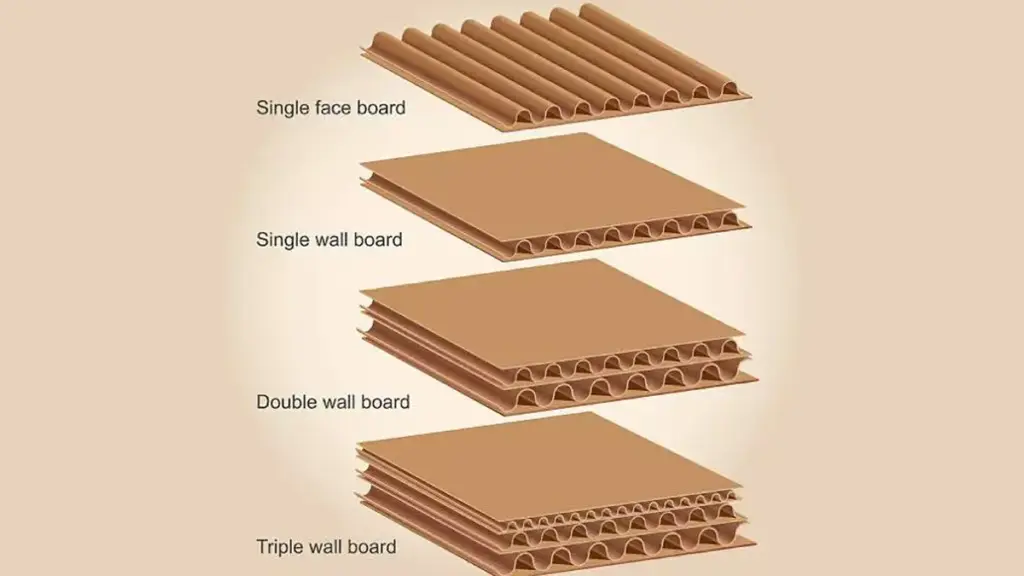

Single-Face Board

Single-face board consists of one layer of fluting glued to a single linerboard. It is flexible and often supplied in rolls for wrapping or interleaving between products. This type offers minimal rigidity but excellent cushioning, making it suitable for protecting delicate items like glassware or ceramics during internal packing.

Single-Wall Board

Single-wall, also called double-face, has one fluted medium sandwiched between two linerboards. It is the most common structure for standard shipping cartons due to its balance of cost and strength. Single-wall boxes are widely used for e-commerce packaging, retail shipping, and lightweight industrial goods where moderate stacking strength is sufficient.

Double-Wall Board

Double-wall board features two layers of fluting and three linerboards, providing significantly enhanced compression strength. These are chosen for heavier products, bulk shipments, or items requiring additional protection during long-distance transport.

- BC Combination – Combines B and C flutes, offering strong stacking strength from C flute and high crush resistance from B flute, suitable for heavy shipments requiring balanced protection.

- EB Combination – Uses E and B flutes, providing a thin profile for better printing while maintaining rigidity, ideal for retail packaging with structural strength.

- AC Combination – Merges A and C flutes, delivering maximum cushioning and compression resistance, commonly applied to industrial or export packaging of fragile, heavy products.

Triple-Wall Board

Triple-wall board consists of three fluted mediums and four linerboards, forming the strongest corrugated structure available. It is used in export crates, automotive components, and other high-weight applications where wooden packaging alternatives are being replaced.

- AAA Combination – Provides the highest durability and stacking strength, ideal for industrial machinery and extremely heavy goods requiring maximum protection.

- ACC Combination – Balances heavy cushioning from A flutes with moderate rigidity from C flutes, suitable for fragile but weighty products.

- ABC Combination – Combines different flute sizes to optimize both rigidity and impact absorption, frequently used in export crates and automotive components.

These structural variations allow manufacturers to tailor packaging performance to product weight, fragility, and shipping requirements, ensuring efficient protection and material use.

Common Corrugated Box Types and Their Relation to Flute Structures

Corrugated box types refer to the finished packaging styles formed from single‑wall, double‑wall, or triple‑wall boards. Understanding these box formats is essential for aligning flute selection with end‑use performance, cost, and branding requirements.

Regular Slotted Container (RSC) is the most widely used style, featuring four flaps of equal length meeting at the center when closed. RSC boxes typically use C or B flute in single‑wall form for general shipping, but double‑wall BC combinations are selected for heavier loads.

Full Overlap (FOL) boxes have flaps that fully overlap, adding reinforcement on the top and bottom surfaces. This design is often paired with A‑ or C‑flute for bulk storage or products requiring greater puncture resistance.

Die‑Cut boxes are custom‑shaped containers created using steel‑rule dies, commonly found in retail or display packaging. These boxes often incorporate E or F flutes for fine printing and precise folding, especially in cosmetics, electronics, or subscription box markets.

Telescoping and multi‑piece boxes are used for tall or fragile items requiring adjustable height or added structural strength. These frequently utilize double‑wall or even triple‑wall configurations such as BC or ACC flutes to ensure adequate compression resistance during stacking.

By matching box style with appropriate flute types in corrugated boxes, packaging engineers can achieve optimal protection, material efficiency, and visual presentation across diverse shipping and retail environments.

How to Choose the Right Flute Types in Corrugated Boxes?

Selecting the appropriate flute types in corrugated boxes is crucial for balancing protection, cost, and brand presentation. Each flute offers distinct performance characteristics, and matching them to the product’s needs ensures packaging efficiency throughout the supply chain.

Application-Based Matching

- E-commerce and Retail Packaging: E and F flutes provide thin profiles and excellent printing surfaces, suitable for branded mailers and retail-ready boxes.

- Food and Beverage: A and C flutes deliver superior cushioning for glass bottles or canned goods, while B flutes work well for trays and displays.

- Electronics and Consumer Goods: C or E flutes strike a balance between protection and compact design for items requiring both cushioning and aesthetic presentation.

- Heavy Industrial and Export: Double- or triple-wall BC and AC combinations are chosen for machinery, automotive parts, or bulk shipments needing high compression strength.

Key Factors to Consider

- Product weight and fragility: Heavier or delicate products require thicker flutes like A or C for cushioning.

- Print quality and branding: Fine graphics are better supported by E or F flutes with smoother surfaces.

- Shipping and storage conditions: Thin flutes save space and reduce freight costs, while thicker ones resist stacking pressure.

- Sustainability and cost: Lightweight microflutes lower material usage and improve recyclability without compromising protection.

By integrating application requirements with these selection criteria, packaging engineers can optimize different types of flutes in corrugated box designs for durability, cost-effectiveness, and sustainability.

Conclusion

Knowledge of flute types in corrugated boxes enables packaging teams to choose structures that meet protection, printability, and cost requirements. Evaluating A to F flutes and wall combinations ensures each product’s packaging is optimized for shipping, storage, and retail presentation.

PackCCP specializes in OEM and ODM corrugated packaging, offering structural engineering and full‑color printing expertise for global clients. Their solutions are certified for quality and designed for diverse industries.

Reach out to PackCCP for tailored corrugated packaging that supports your product and brand goals.