Imagine you are preparing a shipment of fragile products. You need boxes that protect items, fit your logistics system, and are cost-effective. How do you choose the right corrugated box? Which type, wall construction, or flute grade is best for your needs?

This corrugated box buying guide provides clear answers. It explains what corrugated boxes are, how they are made, the common types, and their uses across industries. You will also learn about sustainability, reciclabilidad, opciones de personalización, and key quality considerations. Whether sourcing standard boxes or designing custom packaging, this guide gives the practical and technical knowledge needed to make informed decisions and ensure your products arrive safely.

What Is a Corrugated Box?

A corrugated box is a packaging container made from corrugated fiberboard, which has a wavy, fluted layer between two flat layers of paper. This structure gives the box strength and makes it ideal for shipping products safely.

But what is the difference between cardboard and corrugated? Cardboard refers to a single layer of flat paperboard, commonly used for lighter packaging, like retail boxes. En contraste, corrugated material includes the fluted layer, which adds strength and cushioning, making it suitable for heavier and more fragile items.

Caja de cartón corrugado vs.. Caja de cartón

Through cardboard and corrugated, we get the two common types of boxes we use every day: the corrugated box and the carton box. While both serve as packaging solutions, they have key differences that determine which is best for your needs.

| Característica | Caja corrugada | Caja de cartón |

|---|---|---|

| Estructura | Made from corrugated fiberboard (fluted) | Made from solid, flat paperboard (non-fluted) |

| Fortaleza | High strength, ideal for shipping | Lighter strength, used for retail packaging |

| Weight Capacity | Can handle heavier loads | Best for light to medium-weight products |

| Manufacturing Purpose | Used for shipping and storage | Often used for retail, point-of-sale displays |

| Common Use | Envío, fragile items, industrial goods | Small items, embalaje al por menor |

How Are Corrugated Boxes Made?

A simple box hides many steps. What follows is a clear walk-through of the making process—step by step. For the full technical detail, see “How Corrugated Boxes are Made.”

1. Paper to board. Mills supply two papers: linerboard and corrugating medium. The medium is formed into a wave (the flute) and glued to a liner with starch adhesive. Heat and pressure set the bond.

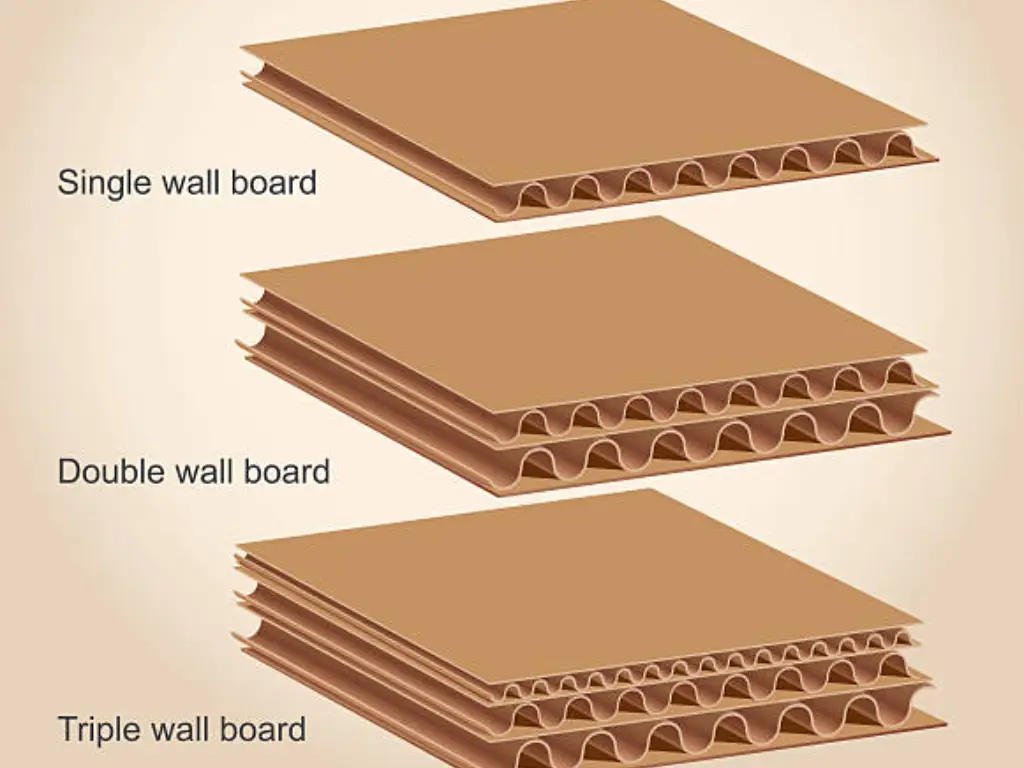

2. Single, double, or triple wall. The corrugator can add more flute-liner pairs to build double-wall or triple-wall board. More walls mean higher stacking strength and better cushioning, but also more weight and cost.

3. Sheet conditioning. Boards are trimmed, moisture-balanced, and stacked to rest. Stable moisture reduces warp and keeps print quality consistent.

4. Printing and conversion. Sheets run through flexographic (or digital) print. Then they’re slotted, scored, and die-cut into the required box layout (RSC, FOL, die-cut styles).

5. Folding, joining, and checks. Blanks are folded and glued or stitched. Inline checks verify dimensions and bonds; sample boxes are tested for ECT or burst strength. Finalmente, boxes are bundled, palletized, and shipped flat for efficient handling.

Types of Corrugated Boxes

Corrugated boxes vary in strength, weight, and performance, shaped by three key factors—wall construction, flute grades, and box styles. The following sections will walk you through these three factors and help you identify the most suitable packaging solution.

Wall Constructions

Pared simple corrugated board has one flute layer sandwiched between two liners. It is light and affordable, making it a common choice for everyday e-commerce packaging and retail shipping.

Double-wall uses two fluted mediums and three liners. This structure increases stacking strength and puncture resistance. It is often selected for industrial goods, export cartons, or shipments that face long transit routes.

Triple-wall consists of three flute layers and four liners. Its durability approaches that of wooden crates, making it suitable for automotive parts, heavy equipment, and other high-weight applications.

As wall thickness increases, so does compression strength and protection against moisture. Sin embargo, added weight and cost must be balanced against the actual shipping requirements.

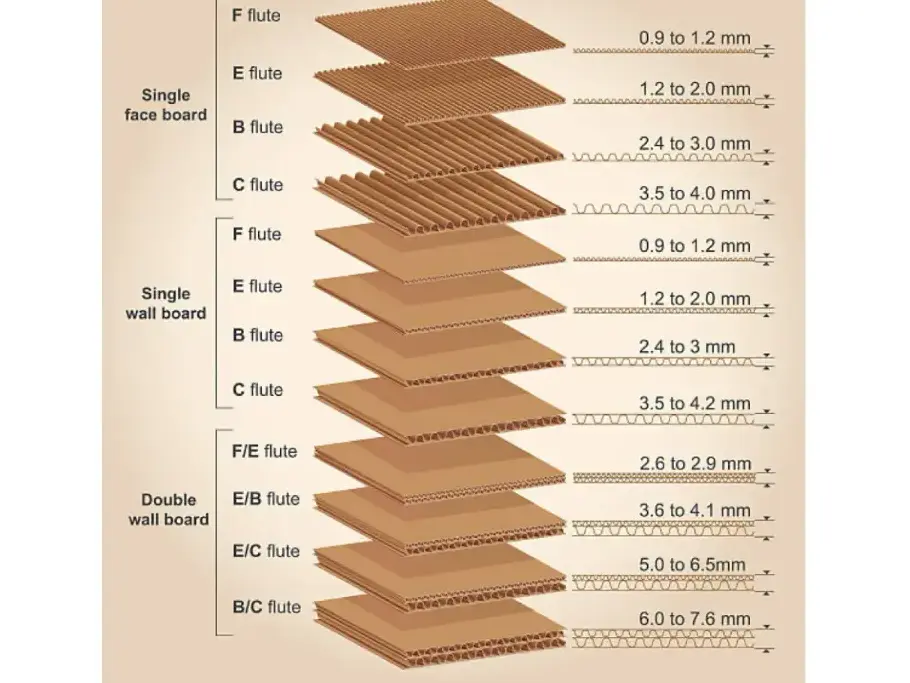

Flute Types

Flute types impacts both structural strength and packaging aesthetics. Below is a comparison:

| Tipo de flauta | Espesor | Fortaleza | Common Use |

| una flauta | ~4.5 mm | Excellent cushioning | Fragile items |

| Flauta si | ~3.2 mm | High crush resistance | Food trays, retail packs |

| Flauta C | ~3.9 mm | Balanced performance | General shipping boxes |

| y flauta | ~1.6 mm | Great print surface | Retail & custom packaging |

| F flauta | ~0.8 mm | Thin, fine finish | Small-format retail boxes |

- C-flute is the most common choice for shipping because it balances cushioning and stacking strength.

- E-flute y F-flute are thinner, offering compactness and a smooth surface for printing—ideal in retail and display packaging.

- A-flute y B-flute, by contrast, provide rigidity and crush resistance, making them suitable for stacked loads and protective packaging.

In double-wall boards, flute combinations enhance performance:

- BC flute pairs B-flute’s crush resistance with C-flute’s cushioning, widely used in export and industrial cartons.

- EB flute combines print-friendly E-flute with strong B-flute, ideal for branded retail packaging or fragile items.

- AC flute maximizes cushioning and stacking strength, suited for heavy or vibration-sensitive goods.

Triple-wall boards often use ACA or BAC configurations, which provide high compression strength and durability. These boards are chosen for heavy-duty logistics and even can achieve performance levels comparable to wooden crates.

Box Styles

Box style defines how corrugated board is cut, folded, and locked together. Each style serves a unique purpose, from basic shipping to high-end retail packaging.

RSC (Contenedor ranurado regular): The most common style, with equal flaps that meet at the center. It is low-cost, easy to produce, and works well on automated lines.

FOL (Full Overlap Slotted Container): Features overlapping outer flaps for extra top and bottom strength. Best for heavy goods that need secure support.

HSC (Contenedor con media ranura): Similar to RSC but with one open side. Often used for products needing quick access or shelf display, sometimes paired with a lid.

Cajas Troqueladas: Custom-made with steel dies to match product shape. Popular in cosmetics, electrónica, and retail, offering both product fit and branding space.

Telescopic Boxes: Made of two pieces (top and bottom) that slide together. Ideal for long or irregular goods, giving adjustable height and even strength distribution.

The right box style gives you the mix of strength, costo, and function your products need. With the basics of structure in mind, have you chosen your corrugated boxes yet? If not, no worries—we can look at it from another angle!

Industries Uses of Corrugated Boxes

If box styles still feel tricky, let’s shift focus. Corrugated boxes prove their value in real industries because they are light, protective, and easy to customize—making them the go-to choice across sectors:

- E-commerce and Retail

RSC boxes with branding are common for deliveries. They are stackable, rentable, and often paired with paper inserts for eco-friendly unboxing.

- Industrial and Manufacturing

Heavy tools or machinery require double- or triple-wall boxes. Reinforced FOL or pallet-ready styles are preferred for export and long-distance freight.

- Food and Agriculture

Vented trays keep fresh produce safe, while FDA-approved or wax-coated liners add moisture protection for cold-chain logistics.

- Medical and Pharmaceutical

Die-cut inserts protect vials and instruments. Clear printing on the outer box ensures compliance and safe handling.

- Exhibition and Display

E-flute boxes deliver sharp graphics and are customized for retail or point-of-purchase displays.

From protecting fragile glassware to creating a strong brand moment, corrugated boxes adapt to every need and remain vital across industries.

Are Corrugated Boxes Recyclable and Biodegradable?

Corrugated boxes also stand out for their environmental advantages, which makes them a popular choice in sustainable packaging. Most are highly recyclable since they are made from kraft paper or recycled fibers. A box can usually go through 5–7 recycling cycles before fibers lose strength. Water-based inks and starch glue keep them fully recyclable, while coatings like wax or plastic film reduce this ability. Buyers should always check with suppliers to confirm compatibility with local recycling systems.

In addition to recyclability, corrugated fiberboard is also biodegradable, meaning it can safely return to nature. Under composting conditions, it often breaks down within 3–6 months. To qualify as fully biodegradable, the material must avoid polymer coatings, synthetic adhesives, or UV inks. Verified standards such as ASTM D6400 or EN 13432 are useful indicators. Together, these qualities show why corrugated boxes remain a reliable solution for eco-friendly packaging decisions.

Final Considerations When Choosing Corrugated Boxes

Before placing an order, buyers should look at two things: box performance and supplier reliability. Missing either can lead to higher costs or packaging failures. Here’s a quick checklist you can use before placing an order:

| Factor | Por qué es importante | What to Check |

|---|---|---|

| 📊 Quality Testing | Ensures the box performs under real stress | -Cobb (moisture) -TEC (stacking) -FCT (flute strength) -Mullen (burst) (look for ASTM D642 or ISOcertification stamps) |

| 🎨 Personalización | Balances branding, protection, and usability | -Printing method -Coatings, die-cuts -Insertos -Ergonomic handles |

| 🤝 Supplier Reliability | Reduces risk and ensures scalable supply | -ISO 9001 / FSC certifications -Design support -Fast sampling -Production capacity |

| 💰 Rentabilidad | Impacts budget and logistics optimization | -Compare unit cost -Shipping volume efficiency -Bulk discounts |

| 🌱 Sostenibilidad | Aligns with eco-goals and brand reputation | -Use of recycled content -Recyclability & biodegradability -FSC/PEFC sourcing |

Choosing corrugated boxes comes down to testing, personalización, and supplier reliability. Together, these ensure strength, sostenibilidad, and cost-efficiency—key takeaways from this buying guide. Entonces, which factor matters most for your business?

En PaqueteCCP, we combine ISO 9001 and FSC certifications with years of OEM personalización experience for global brands like Disney. From structural design to custom branding, we deliver reliable and flexible corrugated solutions. Ready to start your packaging project? Contact us today for tailored support.