From shipping your online orders to protecting fragile electronics, from storing household items to displaying products in stores—why are corrugated boxes everywhere in packaging? Their strength, affordability, and eco-friendliness make them the preferred choice. This article explores how they’re made, their benefits in logistics and branding, industry-specific uses, and compliance with global standards, helping you select packaging that is both practical and reliable.

What Are Corrugated Boxes and How Are They Made?

Corrugated boxes are made from corrugated fiberboard, which sandwiches one or more fluted layers between flat linerboards. This clever layered structure makes the boxes strong yet lightweight, so they can protect products during shipping, stack neatly in storage, and still look good for retail display.

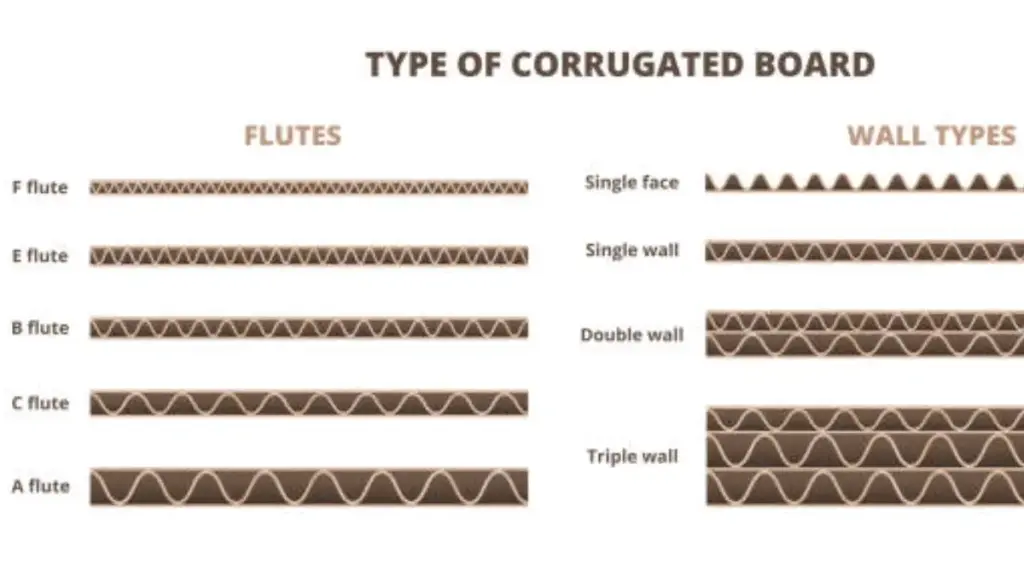

The process behind them is surprisingly precise. Paperboard is first made from kraft or recycled paper. The fluted medium is then shaped through corrugating rolls to add strength. These fluted sheets are glued between linerboards to form single-wall, double-wall, or even triple-wall boards. Finally, the boards are cut, creased, and printed to meet custom shapes and branding needs.

If you want to learn more, click here to see the full corrugated boxes manufacturing process.

Kosteneffizienz

Corrugated packaging remains a go-to choice for many companies thanks to its cost-effectiveness. Compared with plastic crates or wooden boxes, corrugated materials are inexpensive, lightweight, and recyclable, helping reduce both upfront and long-term logistics costs.

- Lightweight design

Corrugated fiberboard provides high strength at low weight, lowering freight costs for air and ground transport. E‑commerce sellers, for example, save on last-mile delivery while keeping fragile products well-protected.

- Space-saving

Boxes ship and store flat, optimizing warehouse space and simplifying distribution. This feature supports efficient palletization and automated packaging lines, allowing companies to minimize storage costs and improve throughput in fulfillment centers such as those operated by Amazon.

- Scalable production

Corrugated packaging can be manufactured quickly in standardized or custom formats. High-speed converting lines lower per-unit costs for large seasonal campaigns, such as consumer electronics launches or holiday promotions, without compromising structural performance.

- Damage reduction

Multi-wall options and varied flute profiles provide superior impact and compression resistance, reducing transit damage and related returns. This not only protects margins but also preserves customer satisfaction and brand trust in competitive retail environments.

- Supply chain adaptability (additional factor)

Corrugated boxes integrate seamlessly with modern logistics systems, from automated sorters to IoT-enabled tracking. Standard dimensions and barcoding compatibility simplify inventory management and cross-docking, further cutting operational costs and waste.

For sectors like e-commerce and FMCG, packaging efficiency directly impacts profit margins. Studies show that optimized corrugated solutions can cut packaging costs by 15–25%, often outweighing initial investments in design and customization.

Sustainability Matters

Nachhaltigkeit is a key factor when choosing packaging. Corrugated boxes are widely recognized as an eco-friendly option, meeting both consumer expectations and regulatory requirements.

- Recyclability

Most corrugated boxes contain 70–100% recycled fiber and can be recycled up to seven times, reducing raw material demand and keeping waste out of landfills.

- Renewable sourcing

Top manufacturers use Forest Stewardship Council (FSC®) certified paper, ensuring fibers come from responsibly managed forests and supporting corporate sustainability goals.

- Lower carbon footprint

Their lightweight design reduces fuel consumption during transport, helping companies cut carbon emissions—a crucial factor for meeting Scope 3 targets.

- Compliance with global standards

Corrugated boxes comply with global standards, such as the EU Packaging and Packaging Waste Directive and U.S. EPA guidelines, making cross-border shipping simpler and less costly.

This strong sustainability profile also explains why corrugated cardboard is used in food packaging, like pizza boxes, thanks to its heat retention, biodegradability, and compliance with food-contact safety standards (Z.B., FDA 21 CFR).

Customization and Branding

Corrugated packaging does more than protect products—it also serves as a powerful branding tool. With modern printing and structural design, businesses can turn packaging into a marketing asset that enhances customer experience.

- Structural design

Sondergrößen, die-cut windows, and inserts help products stay secure and look appealing when unboxed, especially for electronics and premium items.

- Printing technologies

Flexography, digital, and litho-laminate printing allow high-resolution logos, graphics, and QR codes, boosting brand recognition and creating memorable unboxing moments for e-commerce or subscription boxes.

- Special coatings

Moisture-resistant or grease-proof layers preserve packaging integrity and product safety, crucial for food, pharmaceutical, and sensitive items.

- Retail‑ready packaging

Boxes designed for direct shelf display reduce restocking labor and improve visual merchandising, widely used in supermarkets and large retailers for food and personal care products.

- Security features

Tamper-evident seals or reinforced flaps prevent unauthorized access and protect high-value items like cosmetics or small electronics.

Corrugated boxes protect products while enhancing brand experience, offering clear advantages over plain cartons or generic packaging.

Corrugated Box Types

Corrugated boxes vary in wall construction—single-wall, double-wall, and triple-wall—and flute profiles such as A, B, C, E, and F flutes. Each combination offers distinct benefits: A-flute provides superior cushioning for fragile goods; B-flute offers stacking strength for retail displays; E- and F-flutes are thinner, suitable for small consumer goods and high-quality printing.

From a physical performance perspective, corrugated fiberboard provides impact protection, compression resistance, and shock absorption, which are critical for long-distance shipping. This explains why use corrugated boxes for packaging across industries where reducing damage rates directly lowers costs and enhances customer satisfaction.

Industry Applications of Corrugated Boxes

Think about how differently a fragile glass vase, a box of pizza, or a shipment of books needs to be packed—each calls for a specific type of corrugated box that balances protection, kosten, and presentation.

| Industry | Recommended Box Type | Benefits |

| E-Commerce (Amazon, Shopify vendors) | Single or double-wall with B/C flute | Balances protection and weight; easily branded for unboxing experience |

| Essen und Getränk (Pizza, Produce) | E-flute or B-flute single-wall | Heat retention, breathability, cost efficiency; answers why is corrugated cardboard used for pizza boxes |

| Elektronik | Double-wall with anti-static liners | Impact and vibration protection; prevents electrostatic damage |

| Industrial/Heavy Goods | Triple-wall with A/B flute combo | High compression strength for machinery or automotive components |

Standards and Future Trends in Corrugated Packaging

When it comes to packaging, it’s not just about the box itself—global standards make sure it’s safe, dauerhaft, and sustainable. From ISO 18604 on environmental impact to ISTA tests for transit performance, these benchmarks give businesses and supply chain partners confidence in consistent quality.

- Smart packaging: Integration of QR codes or RFID for traceability and inventory management.

- Lightweight innovation: Enhanced strength-to-weight ratios using advanced fluting designs.

- Circular economy focus: Greater emphasis on closed-loop recycling and biodegradable coatings.

- Automation compatibility: Standardized box dimensions designed for robotic packing lines.

As packaging trends evolve, knowing these developments allows businesses to stay ahead and reinforces why corrugated boxes remain a smart choice in changing markets.

Abschluss

Corrugated boxes combine protection, cost efficiency, und Nachhaltigkeit, making them an essential packaging choice for industries such as food, E-Commerce, and electronics.

For businesses seeking a reliable partner, Packccp stands out with full in‑house production, FSC/BSCI/CE/ROHS certifications, and strong customization capabilities across structural design and branding. Its fully eco‑friendly process ensures compliance and global market acceptance.

Kontaktieren Sie uns today to explore tailored Wellpappverpackung solutions that enhance both performance and brand value.