Wenn es um benutzerdefinierte Papierboxverpackungen geht, Details sind wichtig. Ein Dielin ist die Blaupause hinter jedem gut strukturierten, Paket für Druck-Perfekte. Es zeigt genau, wo Ihre Box geschnitten wird, gefaltet, klebt - und wie Ihr Branding jedes Panel umwickelt wird.

Wenn Sie benutzerdefinierte Boxen mit entwickeln Packccp, Das Verständnis von Dielininen hilft Ihnen dabei, die Kontrolle über Ihre Verpackungsqualität zu übernehmen, Vermeiden Sie kostspielige Fehler, und sorgen Sie für eine reibungslose Produktionsreise vom Konzept bis zur Fertigstellung.

Was ist ein Dielin in Papierboxverpackung??

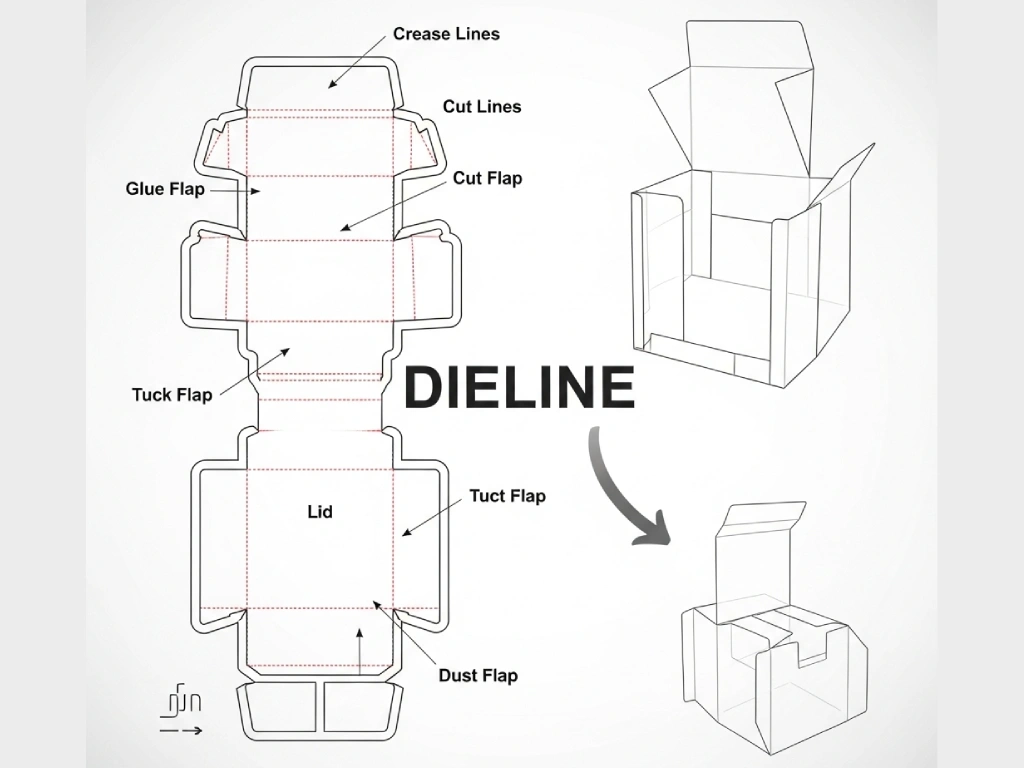

Ein Dielin ist ein flaches Layout, das die Form und Struktur Ihrer Box zeigt, bevor es zusammengebaut wird. Betrachten Sie es als die “Zeichnung des Ingenieurs” Ihrer Verpackung. Es skizziert:

- Linien geschnitten - wo die Schachtel gekürzt ist

- Faltlinien - Wo Falten gemacht werden, um die Box zu formen

- Blutungszonen - Für die Erweiterung von Hintergrundkunstwerken

- Sichere Zonen - Bereiche, in denen essentielle Text und Logos innen bleiben sollten

- Klebebereich - Panels, die zusammen eingehalten werden

Bei packccp, Dieline herunterladen werden immer im Vektorformat erstellt, um die Standards der industriellen Stanze zu erfüllen und eine hohe Druckgenauigkeit zu gewährleisten.

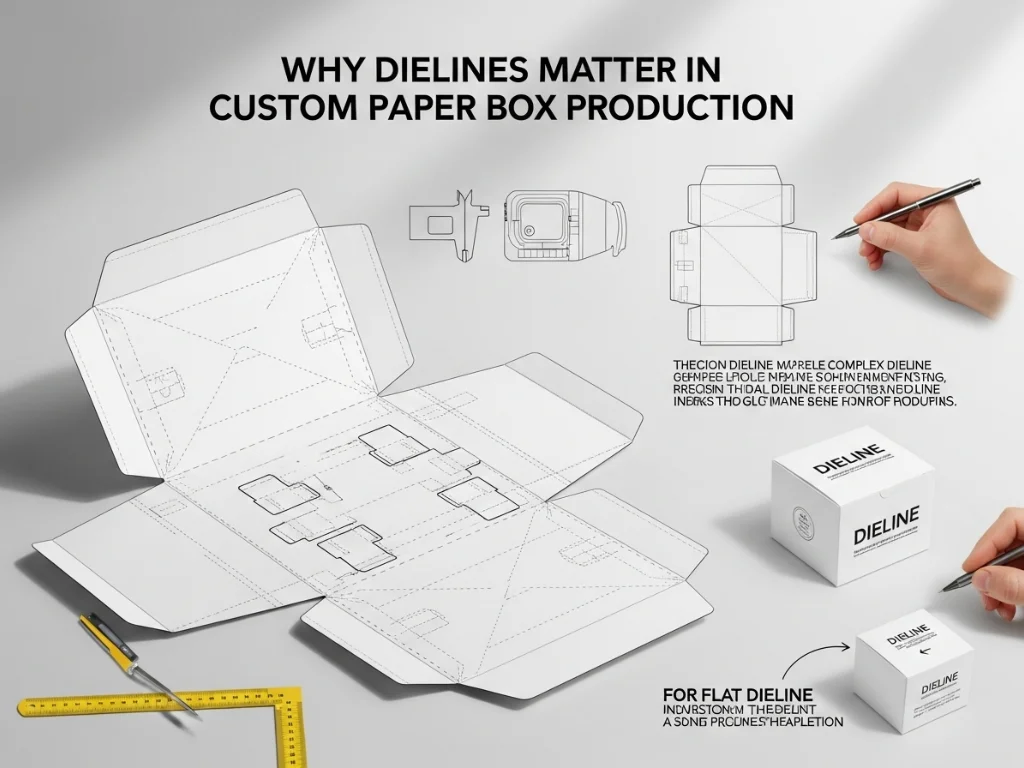

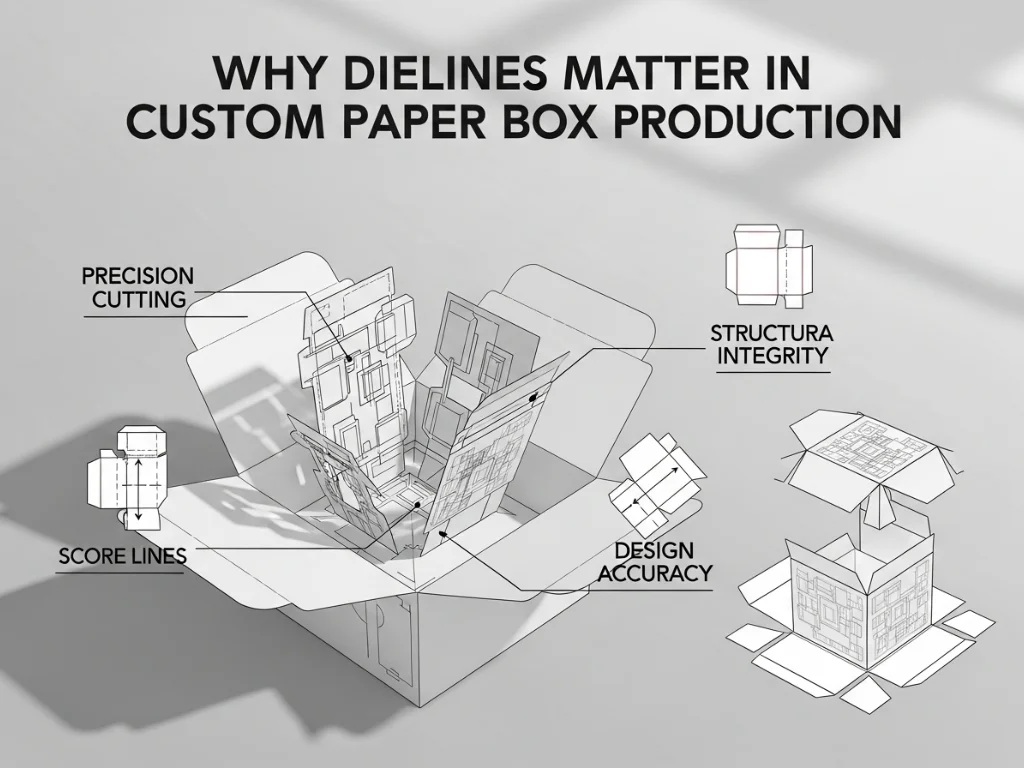

Warum Dielines in der Produktion von benutzerdefinierten Papierkasten wichtig sind

Ein Dieline ist nicht nur ein technischer Schritt - es ist die Grundlage für zuverlässige, Markenkonsistente Verpackung. Hier ist der Grund, warum es richtig ist:

✅ Fehlerprävention

Ein genaues Dielin verhindert falsch ausgerichtete Kunstwerke, Faltungsfehler, und Kastengrößenprobleme. Es ist weitaus billiger, Layoutfehler in der Designphase zu beheben als nach Beginn der Produktion.

✅ Bessere Kommunikation

Von Ihrem Grafikdesigner bis zu Ihrem Box -Lieferanten, Jeder bezieht sich auf den Dielin. Es ist die gemeinsame Sprache in der Produktionskette.

✅ Konsistenz über Chargen hinweg

Egal, ob Sie produzieren 500 Einheiten oder 50,000, ein validiert Dieline herunterladen stellt sicher, dass jede Box der gleichen Struktur und Spezifikationen folgt.

Wie ein Verpackungsdielin für Papierkästen erstellt wird

Bei Packccp, Unser Strukturteam folgt normalerweise diesen Schritten:

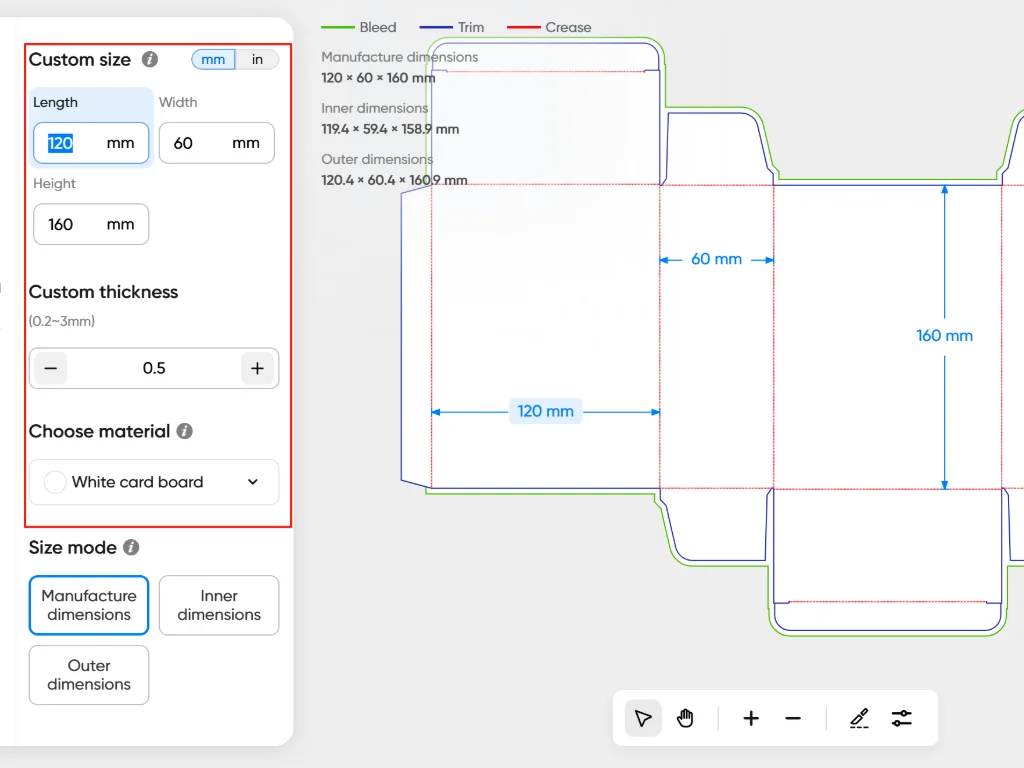

- Wählen Sie den Boxstil aus - Tuck Top? Schublade? Magnetklappe?

- Messen Sie das Produkt - Um sicherzustellen, dass die Box genau und sicher passt

- Bauen Sie das Dielin in Vector -Software auf - Verwenden von Tools wie Artioscad oder Adobe Illustrator

- Definieren Sie technische Markierungen - Einschließlich:

- Linien geschnitten (solide schwarz)

- Faltlinien (Rot)

- Blutungsbereich (grüne Grenze, 3mm)

- Zähnung (schwarz gepunktet)

- Kleberzonen (geschlüpfte Panels)

- Exportieren zur Überprüfung & Platzierung von Kunstwerken - Oft im AI- oder PDF -Format

Unser Team kann auch 3D -Modelle generieren Dieline herunterladen Um die Vorschau des fertigen Ergebniss vor der Produktion zu unterstützen.

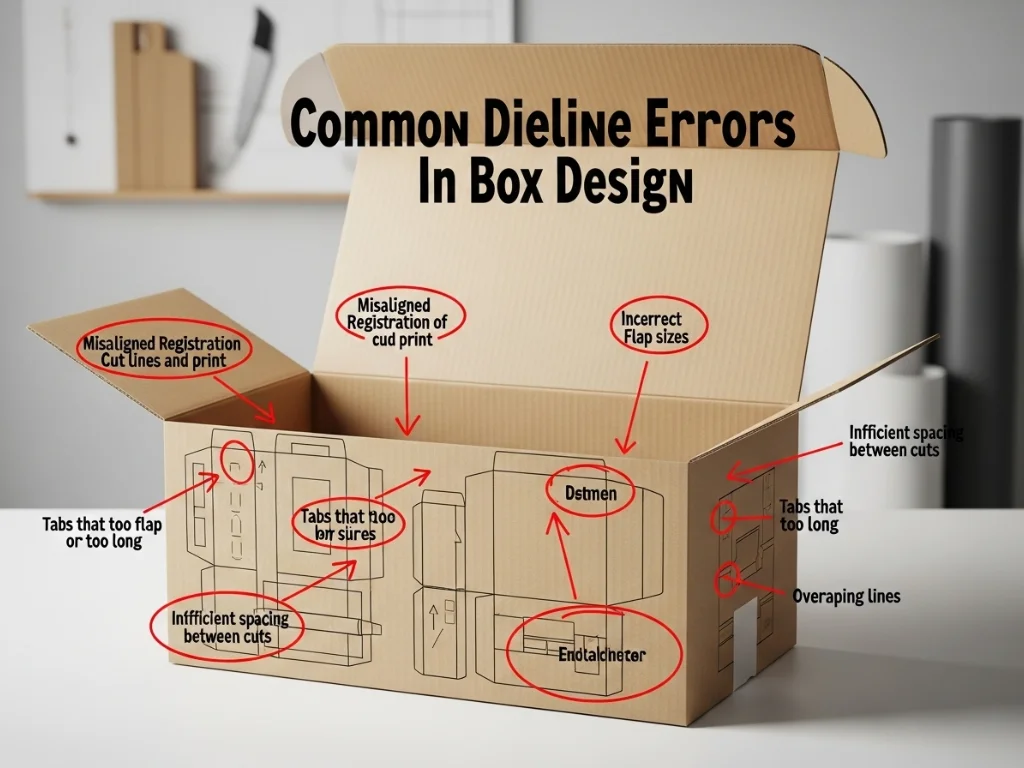

Gemeinsame Dielinfehler im Boxdesign

Sogar erfahrene Designer vermissen manchmal kleine -, aber kostspielige - Konstruktionen:

- Kein Blutspanne - führt zu weißen Kanten im endgültigen Druck

- Kunstwerke über Falten - Text platziert zu nahe an Knicklinien kann verzerren

- Falsches Dielinformat - Rasterbilder wie JPG oder PNG funktionieren nicht für die Produktion

- Nicht gedruckte Farben - Der CMYK -Farbmodus ist ein Muss für den professionellen Druck

Packccp Angebote Dieline herunterladen Dateiüberprüfungen vor dem Druck, damit Sie diese Fallstricke vermeiden können.

Verpackungsdielinvorlage - was es ist & Wann man es benutzt

Für Marken, die neu in kundenspezifischen Verpackungen sind, mit a Verpackungsdielinvorlage kann Zeit und Kosten sparen. Diese vorgefertigten Vorlagen eignen sich für gemeinsame Boxstile wie Mailer, Tuck-End-Kisten, und Kissenboxen.

Sie können kostenlose Dielinvorlagen untersuchen Pacdora.

Verwenden Sie eine Dielinvorlage, wenn:

- Sie arbeiten mit Standard -Box -Formen

- Ihr Produkt erfordert keine kundenspezifische Größen

- Sie benötigen eine schnelle und wirtschaftliche Verpackungslösung

Gehen Sie Custom If:

- Sie brauchen eine einzigartige Struktur (z.B. Versteckte Magnete, Fenster, Mehrproduktschalen)

- Ihr Produkt hat ungewöhnliche Dimensionen

- Sie zielen auf einen High-End-Markt und möchten, dass Ihr Unboxing-Erlebnis von hervorsticht

Packccp Kann auch Dieline-Vorlagen mit referenzieren oder vollständig benutzerdefinierte von Grund auf neu erstellen.

So arbeiten Sie mit Ihrem Verpackungslieferanten auf Dielines

Ein großartiger Verpackungspartner druckt nicht nur Ihr Dieline - sie helfen Ihnen, es zu verfeinern. Hier erfahren Sie, wie Sie effektiv zusammenarbeiten können:

- Beginnen Sie mit einer physischen Probe - Eine Schachtel flachen, die genau zu dem entspricht, was Sie wollen

- Senden Sie genaue Produktmessungen - Höhe, Breite, Tiefe in mm

- Verwenden Sie klare Dateibezeichnungen - Mark „Schnittlinie,"Faltlinie,"Bluten," usw.

- Fordern Sie eine 3D -Vorschau an - Bei Packccp, Wir bieten diesen Schritt an, um die Struktur vor der vollständigen Produktion zu visualisieren

- Markenrichtlinien teilen - Farbcodes, Schriftarten, Logo -Positionierungsregeln - dies hilft unserem Designteam, Ihren Markenstandards zu entsprechen

Vorlage gegen benutzerdefinierte Dielines, die zu Ihrer Marke passt?

| Besonderheit | Vorlagendieliner | Benutzerdefinierte Dielines von Packccp |

|---|---|---|

| Geschwindigkeit | Schnell zu starten | Erfordert Entwicklungszeit |

| Kosten | Untere | Höherer Setup, Langzeitwert |

| Markendifferenzierung | Beschränkt | Hoch - an Ihre Markengeschichte verteilt |

| Fit & Schutz | Generische Passform | Genau passt zu Ihrem Produkt |

| Erweiterte Funktionen | Nicht verfügbar | Fensterschnitte, Magnete, Soft-Touch usw. |

Immer noch nicht sicher, welche Route zu Ihrem Produkt passt?

Machen Sie sich mit unserem Team in Verbindung, um eine Strukturberatung zu erhalten. Wir führen Sie anhand Ihrer Branche und Ihrer Produktgebrauchsfall an.

Bessere Verpackung beginnt mit einer starken Struktur

Dielines sind nicht nur technische Tools - sie sind der Rahmen für effektive Verpackungen. Ein gut ausgearbeitetes Dieline stellt sicher, dass Ihr Kunstwerk genau so aussieht, wie Sie es sich vorgestellt haben, Ihre Box hält strukturell hoch, und Ihre Produktion läuft reibungslos vom Prototyp zu Palette.

Bei Packccp, Wir drucken nicht nur Dielines - wir helfen Ihnen beim Aufbau von Verpackungen, die funktionieren, um, und verkauft.

👉 Benötigen Sie eine Dielinvorlage oder ein benutzerdefiniertes Layout? Wenden Sie sich an das PackCCP -Team Für eine kostenlose Beratung.