Think of those elegant gift boxes you receive during the holidays or the sleek packaging of a designer watch. These are prime examples of luxury packaging, where rigid boxes stand out for their premium feel and durability. But why choose a rigid box for high-end packaging?

In this guide, we’ll take you through the process of rigid box production, from selecting materials and customizing designs to implementing innovative techniques and sustainable practices, all aimed at delivering top-quality packaging that meets your clients’ needs.

Key Materials for Rigid Boxes

Rigid boxes are premium, sturdy packaging solutions made from thick paperboard, typically ranging from 1.5mm to 3mm in thickness. Known for their high-end feel, these boxes are commonly used to package luxury items such as smartphones, perfumes, Kosmetika, and jewelry.

The first step in producing a rigid box is selecting the right materials, which directly impacts the durability and appearance of the final product.

- Pappe: The primary material used in rigid boxes is paperboard, specifically chipboard, which comes in various thicknesses depending on the strength required. The paperboard provides the rigid, sturdy structure that gives the box its strength and premium feel.

- Covering Materials: After the frame is formed, the outer layer of the box is covered with a variety of materials, such as paper, cloth, or leather. Paper options range from glossy to matte finishes, while cloth or leather gives a more upscale, tactile experience.

- Lining and Inserts: To protect the contents, rigid boxes often feature a lining or interior insert, which may include foam, velvet, or cardboard. These materials cushion the items inside, preventing them from moving or getting damaged during transport.

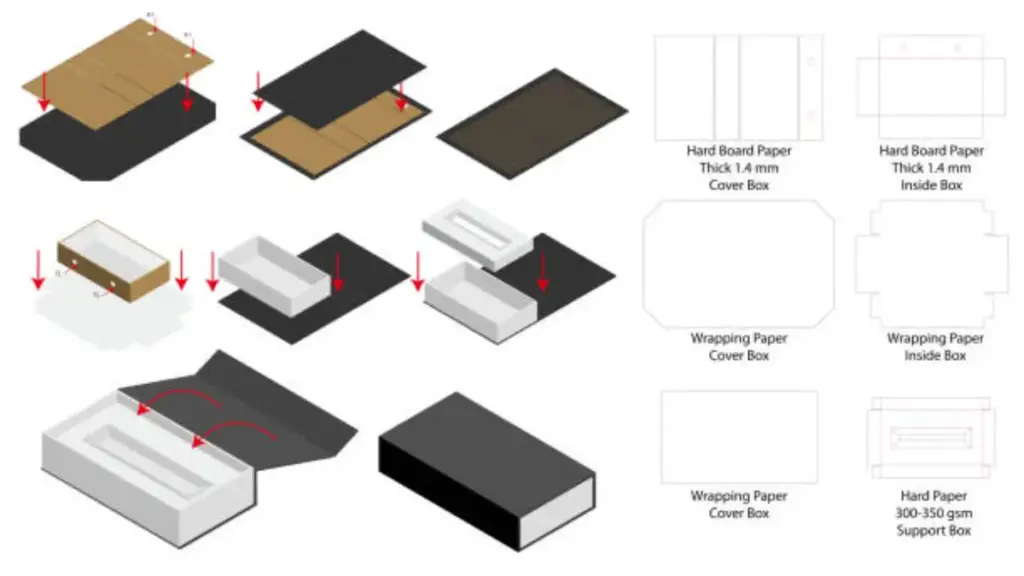

The Steps Involved in Manufacturing Rigid Boxes

The manufacturing process of rigid boxes involves several critical stages, each requiring precision to ensure the final product’s quality and durability. Here’s a closer look at the key steps involved:

Design and Prototyping of Rigid Boxes

The process begins with creating a dieline or template, a precise, flat layout of the rigid box that serves as the blueprint for cutting and folding the paperboard. This step is crucial because a well-made dieline directly impacts the box’s structure and appearance. Once the dieline is finalized, a prototype is created to test the accuracy of the design. This sample box allows manufacturers to assess the fit, form, and function, ensuring that the final product will meet the client’s requirements before full production begins.

Cutting and Shaping the Paperboard

Once the design is approved, the paperboard is cut into the correct shape and size using cutting dies. The chipboard (or greyboard), typically 2-3mm thick, serves as the skeleton of the box. It is cut to the exact dimensions required for the box’s frame. Zusätzlich, scoring dies are used to create creases in the paperboard, ensuring clean and precise folds. This step is essential to maintain the strength and rigidity of the box during assembly.

The outer wrap, or the decorative paper covering, is applied next. This wrap provides the box with its aesthetic appeal, offering a smooth finish for printing or other embellishments. The wrap must fit perfectly around the frame, ensuring a flawless presentation without any wrinkles or defects. The interior, often made of a greyboard or chipboard, provides the box’s structural integrity, making it both durable and strong.

Assembling the Box Frame

The assembled frame forms the rigid structure of the box. During this stage, the cut and scored paperboard pieces are folded and glued together. The glue must be evenly applied to ensure a strong bond without excess residue. It is crucial to carefully assemble the frame to avoid misalignments, as this can compromise the box’s overall strength.

After the frame is glued, it is pressed to ensure that the adhesive cures properly and the components stay securely in place. The edges are also carefully trimmed and smoothed to ensure the box has a clean, polished appearance. In some cases, this process is completed using specialized machinery to guarantee precision and uniformity. This step ensures that the box has the necessary durability and an aesthetically flawless finish to hold its contents safely during transport and storage.

Ensuring Quality in Rigid Box Production

So, you might think that once the box is glued and assembled, the process is done. But here’s where the real quality assurance begins. Ensuring that every rigid box meets both functional and aesthetic standards requires a careful and thorough quality control process.

- Material Inspection

Before production even begins, all materials—such as the paperboard and covering materials—are carefully inspected. This ensures they meet the required standards in terms of thickness, Textur, und Haltbarkeit. After all, the foundation of any great box starts with the right materials

- Structural Testing

It’s not enough for the box to look good on the outside; it also needs to withstand the test of time. Structural tests are performed to assess the box’s strength, such as drop tests to simulate shipping and handling conditions. This ensures the box will protect its contents during transit

- Visual Inspection

Once the box is fully assembled, a detailed visual inspection takes place. This step checks for any defects—misaligned corners, uneven edges, or any excess glue. This ensures every box is visually perfect and built to last

Customization Options for Rigid Boxes

One of the major advantages of rigid boxes is the level of Anpassung they offer. Manufacturers can tailor every aspect of the box, from the size and shape to the color and finish.

| Customization Option | Specifics | Cost Estimate | Practical Application |

| Größe, Form & Typ | Sondergrößen, Formen, and types (Z.B., Flip -Geschenkbox, Foldable Magnetic Box, Starr Schubladenbox) | Moderat bis hoch | Shoes, Elektronik, luxury gift boxes |

| Printing Methods | Offsetdruck, digital printing, embossing, Folienprägung | Moderat bis hoch | Luxury packaging, cosmetic boxes |

| Outer Packaging | Smooth paperboard, textured finishes, soft-touch coatings, fabric wrapping | Low to Moderate | Geschenkboxen, high-end fashion packaging |

| Inner Packaging | Molded foam inserts, velvet lining, custom compartments | Moderat bis hoch | Jewelry boxes, perfume packaging |

| Advanced Accessories | Magnetic closures, ribbon ties, custom inserts | Hoch | Luxury gifts, premium fashion boxes |

Innovative Techniques for Rigid Box Production

As we’ve seen, a rigid box may seem simple, but it’s actually a product of intricate craftsmanship. Jedoch, we’re not stopping there. With the rapid advancement of technology, new innovations are continuously shaping the way we produce rigid boxes. Here are some of the groundbreaking techniques that are changing the game:

Automation and Digital Technologies: Automation is transforming the manufacturing process, making it faster and more precise. Digital technologies streamline tasks like printing and cutting, reducing human error and increasing efficiency.

Advanced Cutting and Molding Techniques: New cutting and molding technologies allow for highly intricate designs, enabling the creation of complex shapes and structures that were once difficult or impossible to achieve.

3D Printing : 3D printing is used in prototyping to quickly produce sample designs. This method speeds up the testing phase and allows for more flexibility in design adjustments.

Virtual Reality: Virtual reality tools allow designers to visualize and test box designs in a virtual environment, ensuring a perfect fit before any physical production takes place.

Smart Packaging: With the integration of IoT, smart packaging enables features like RFID tags or QR codes, allowing consumers to interact with the product packaging digitally, enhancing user experience.

Sustainable Practices in Rigid Box Production

In addition to innovation, Nachhaltigkeit has also become a key focus for us in rigid box manufacturing. Many manufacturers are opting for recycled paperboard, which not only reduces waste but also conserves natural resources. Recycled paperboard is just as durable as virgin materials, yet it significantly lowers the carbon footprint. Zusätzlich, the use of biodegradable inks and water-based adhesives has become more common, ensuring that the final product is easier to recycle and causes less harm to the environment.

On the production side, efficient manufacturing practices are being implemented to further reduce waste. Lean manufacturing techniques optimize production processes, cutting down on energy consumption and material waste. By adjusting machine settings and streamlining workflows, manufacturers are able to produce rigid boxes more efficiently while minimizing their environmental footprint. This dual approach—eco-friendly materials and efficient production—helps companies meet both sustainability goals and consumer expectations.

Abschluss

The process of manufacturing rigid boxes is intricate, requiring careful attention to every detail—from selecting high-quality materials to ensuring precise production standards. Innovation, Anpassung, and sustainability are key drivers in producing packaging that not only protects but also enhances the product’s appeal. Staying on top of these trends allows manufacturers to meet the increasing demands for premium packaging solutions that reflect both quality and environmental responsibility.

Bei Packccp, we specialize in creating custom rigid boxes that blend innovation with sustainable practices. Our commitment to quality and craftsmanship ensures that every box we produce meets the highest standards. Bereit, Ihre Verpackung aufzuwerten? Contact us today and let us help bring your vision to life with our premium rigid box solutions.