Choosing the right packaging is crucial for businesses, whether you’re looking to optimize shipping, enhance branding, or reduce costs. With many options available, how do you decide between corrugated box vs. carton box?

In this article, we’ll explore the key differences between these two packaging types, focusing on materials, strength, print options, cost, and sustainability. We’ll also look at the manufacturing processes and key factors affecting your packaging decisions. By the end, you’ll have the knowledge to pick the best packaging for your products and business.

What Are Corrugated Boxes and Carton Boxes?

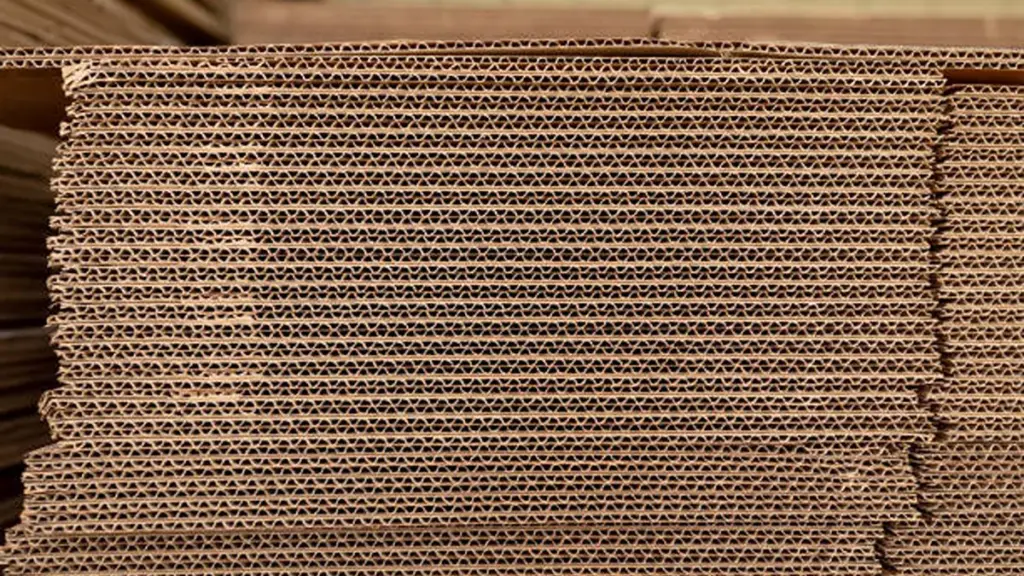

Corrugated boxes are made from a multi‑layer structure, consisting of a fluted paper medium sandwiched between two linerboards. This design offers exceptional strength, making them ideal for shipping and storage fragile items. The fluted structure provides cushioning and impact resistance, ensuring product safety during transit.

Carton boxes are constructed from a single sheet of solid paperboard, typically made of bleached sulfate (SBS) or recycled materials. They are lighter and thinner than corrugated boxes, focusing on smoothness and print quality. Carton boxes are commonly used for retail packaging, where branding and shelf appeal are key, though they provide less durability for shipping.

Material and Manufacturing Comparison

Corrugated boxes are made from kraft linerboard and a corrugated medium, both sourced from virgin or recycled paper. The manufacturing process involves fluting the medium through heated rollers, then gluing it between two linerboards. This structure provides strength and cushioning, and different flute profiles—A, B, C, E, and F—offer various performance characteristics. The process ensures compliance with ISO 9000 for quality control and can be further tested with performance measures like the Edge Crush Test (ECT).

In contrast, carton boxes are made from solid bleached sulfate (SBS) or recycled paperboard. The material is calendered for smoothness and is often coated to improve printability and moisture resistance. The manufacturing process includes die‑cutting and folding, making it ideal for packaging retail products. Carton boxes are typically lighter and less durable than corrugated ones but are designed to offer a high‑quality appearance for consumer-facing goods.

Strength, Durability, and Protection Performance

Corrugated boxes deliver exceptional durability because of their fluted multi‑layer structure, which enhances load distribution and resistance to crushing. They are tested for compression strength and shock absorption, making them ideal for long-distance shipments and transport.

- High compressive strength: Supports heavy stacking during palletized transport without deformation, ideal for industrial and e‑commerce shipments.

- Effective shock absorption: The fluting cushions products against vibration and impact, reducing breakage during long‑distance handling.

- Improved moisture tolerance: Can incorporate coatings or wax treatments, enabling use in cold‑chain logistics or high‑humidity environments.

Carton boxes prioritize lightweight design and print quality but offer limited structural performance. Their single‑layer paperboard composition suits retail display rather than rigorous shipping conditions.

- Low compressive strength: Suitable only for light items or non‑stacked packaging; prone to crushing under heavy loads.

- Minimal impact resistance: Requires additional inserts or secondary packaging to protect fragile goods during transport.

- Poor moisture resistance: Susceptible to warping or softening in humid conditions, reducing reliability for long‑haul distribution.

This evaluation of corrugated box vs. carton box performance highlights the protective advantage of corrugated designs in demanding supply chains.

Printing, Branding, and Aesthetic Considerations

When it comes to branding and aesthetics, carton boxes are the clear winner for retail packaging. Their smooth, single-layer structure is perfect for high-resolution printing, allowing businesses to create eye-catching designs that attract consumers. Carton boxes support various finishes like embossing, foiling, and spot UV coatings, enhancing the visual appeal of products on the shelf.

On the other hand, corrugated boxes are more limited in terms of print quality due to their textured surface. While they can be printed with flexographic or digital techniques, the result is less detailed than carton boxes. However, for businesses that need both branding and protection, a common solution is using carton boxes for retail presentation and corrugated boxes for outer shipping protection. This combination offers the best of both worlds—premium branding and reliable shipping.

Cost and Sustainability Factors

When evaluating cost, corrugated boxes tend to be more expensive due to their multi-layer design and the machinery required for production. However, they provide cost-efficiency in bulk shipments, offering durability and strength at scale. In contrast, carton boxes are more affordable for smaller quantities, especially in retail packaging, where lightweight design is key.

From a sustainability standpoint, both packaging options are recyclable, but corrugated boxes often contain a higher proportion of recycled fibers and are widely accepted in curbside programs. They are typically more sustainable in the long run due to their ability to be reused and recycled multiple times. Carton boxes, while recyclable, may include coatings or laminates that can hinder the recycling process, making them less eco-friendly for some uses.

Typical Applications and Industry Use Cases

E‑commerce: Ideal to choose corrugated boxes for shipping fragile items, as they offer superior protection and strength during transport.

Retail Packaging: Carton boxes are the go-to choice for retail displays, offering high-quality printability and an attractive finish for consumer-facing products.

Food and Beverages: Carton boxes are commonly used for packaging dry food items, providing lightweight and cost-effective solutions with excellent branding potential.

Electronics and Appliances: Corrugated boxes provide the necessary durability and protection for shipping delicate electronics, ensuring safe delivery.

Agriculture: Corrugated boxes are widely used in the agriculture industry to safely transport fresh produce, offering moisture resistance and impact protection.

When choosing between corrugated box vs. carton box, businesses should assess product type, shipping requirements, and branding goals to select the most suitable option.

How to Choose Between Corrugated and Carton Boxes for Your Business

Use this table to quickly compare structural, cost, and application differences when selecting optimal packaging for your products.

| Dimension | Corrugated Box | Carton Box |

| Material Structure | Multi‑layered fiberboard with fluted medium for strength and cushioning. | Single‑layer paperboard, smooth surface ideal for retail presentation. |

| Strength & Protection | High compression resistance, ideal for heavy or fragile items. | Lower strength, suitable for lightweight products and retail display. |

| Printing & Branding | Limited print quality (flexographic/digital), basic branding. | High-quality print (offset/digital), ideal for premium finishes. |

| Cost & Sustainability | Higher cost, but recyclable and FSC-certified. | Lower cost, may have coatings that affect recyclability. |

| Typical Applications | E‑commerce, logistics, bulk packaging, electronics, fresh produce. | Retail packaging, food, cosmetics, pharmaceuticals, small-volume items. |

In addition, you should consider product characteristics, logistics demands, and branding goals, such as:

- Weight and Fragility: Heavy or breakable products require corrugated for impact resistance.

- Distribution Model: Long‑distance or multi‑layer stacking favors corrugated; point‑of‑sale packaging favors carton.

- Budget and Volume: Large‑scale shipping benefits from corrugated’s durability; high‑volume retail benefits from carton’s printability.

- Sustainability Targets: Recycled content, recyclability, and certifications influence both options.

Corrugated boxes and carton boxes serve different purposes: protection versus presentation. Corrugated boxes provide strength and durability for shipping and logistics, while carton boxes offer high-quality printing and cost-efficiency for retail. By considering factors like weight, fragility, branding, and sustainability, businesses can choose the best packaging—or use both to maximize benefits.

For optimal packaging solutions, PackCCP offers tailored options that meet both your protective and branding needs.