Corrugated cardboard boxes are the backbone of modern packaging. From e-commerce shipping to premium gift presentations, they offer strength, versatility, and eco-efficiency. But how exactly are they produced? Let’s explore the full process—from raw fiber to finished box—and see why businesses in the U.S., أوروبا, and Australia trust them as both functional carriers and brand assets.

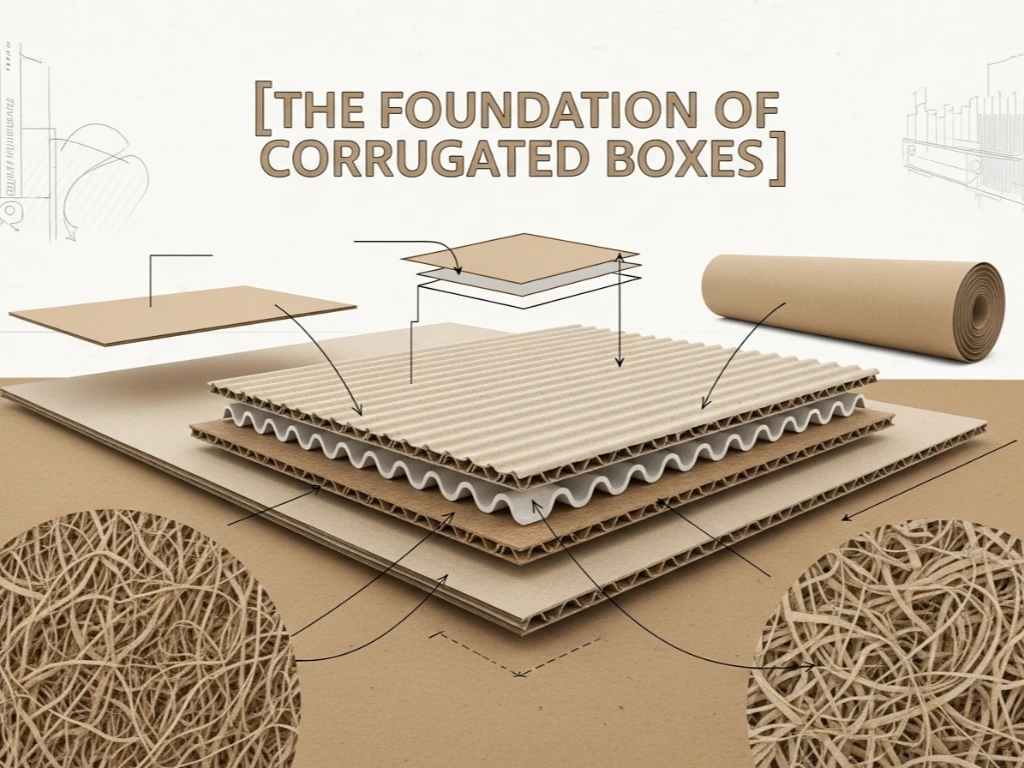

Raw Materials The Foundation of Corrugated Boxes

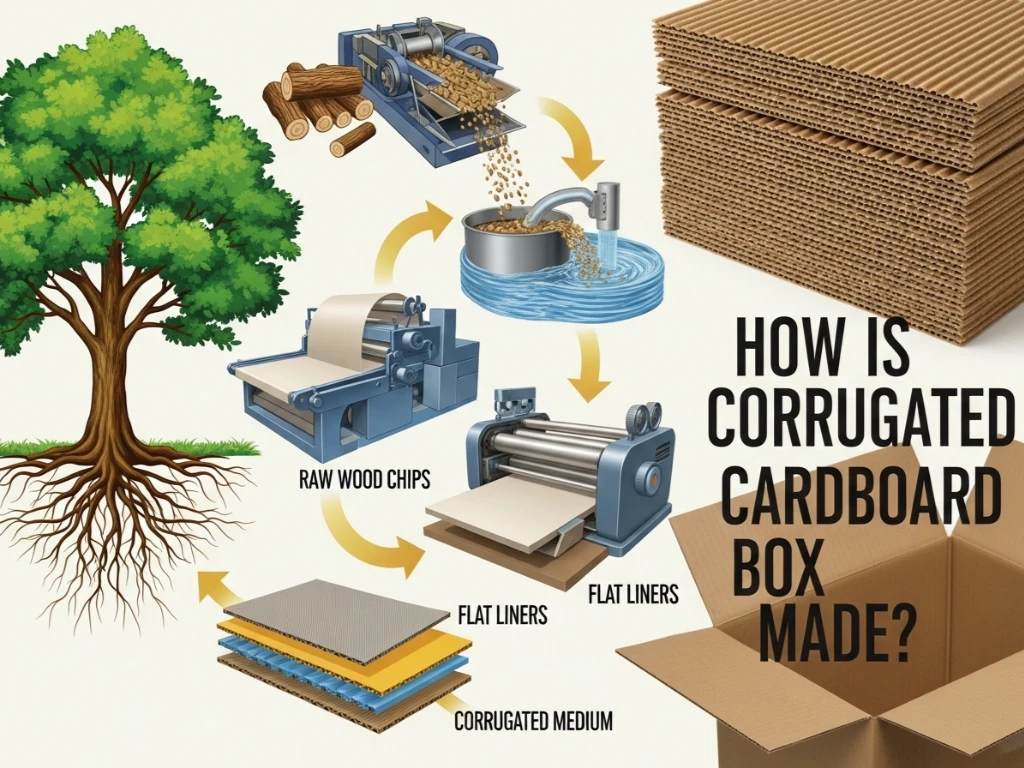

The journey begins with paper. Two key layers form the structure:

- Kraft linerboard – Smooth outer surfaces made from strong virgin fibers (pine, spruce).

- Fluting medium – The inner wavy sheet, often from recycled paper, which provides cushioning.

According to the Fibre Box Association, over 90% of corrugated packaging in North America contains recycled content (source). This balance between virgin fiber and recycled input is what gives corrugated cardboard its unique mix of durability and sustainability.

At Packccp, we help brands choose FSC-certified linerboard, ensuring packaging aligns with environmental standards in Europe and Australia, where eco compliance is tightly regulated.

Steam, Adhesive, and the Role of Corrugators

Transforming paper sheets into durable boards requires precision engineering:

- Steam conditioning softens paper reels, making them flexible for shaping.

- Adhesive bonding uses starch-based glues derived from corn or wheat. These glues are قابلة للتحلل, renewable, and food-safe, making them ideal for sectors like gourmet food and cosmetics.

- Corrugating rolls press the fluting medium into wave-like patterns.

Flute types vary by function:

- A-flute – Large, best for cushioning.

- B-flute – Thin, ideal for retail displays.

- C-flute – Most common, balancing strength and cost.

- E/F microflutes – Preferred for cosmetics and luxury boxes.

Smithers reports that microflute packaging is expanding rapidly, driven by e-commerce and shelf-ready retail designs (source).

From Single Wall to Triple Wall: Building Strength

Corrugated board comes in different wall structures:

- Single-face board – One liner + fluting (lightweight).

- Single-wall board – Two liners sandwiching one flute (standard for shipping cartons).

- Double-wall board – Two flutes + three liners (heavy-duty, long-distance transport).

- Triple-wall board – Three flutes + four liners (wooden crate alternative for exports).

In Europe, double-wall boards are often required for compliance with EU Packaging Waste Directive (PPWD) recycling targets (European Commission). In Australia, APCO’s 2025 National Packaging Targets push suppliers to prioritize recyclable and compostable formats (APCO).

At Packccp, we often recommend double-wall designs for brands shipping across Australia and Europe, where long-distance transit demands higher load resistance.

Cutting, Slotting, الطباعة, and Folding

Once the board is ready, it’s converted into usable box blanks:

- Cutting & slotting – Machines cut precise dimensions and fold lines.

- Flexographic or digital printing – Logos, brand colors, and sustainability messages are applied.

- Folding & gluing – Blanks are glued into flat boxes, ready to be assembled by end users.

According to Statista, the U.S. corrugated packaging market is projected to surpass $74 billion by 2028, fueled by rising e-commerce and demand for custom printing (source).

Packccp adds value by offering premium finishes such as foil stamping, embossing, and laminated wraps—transforming corrugated shipping cartons into branded experiences.

For an in-depth look at packaging blueprints, see our guide: What Is a Dieline in Packaging?

Recycling and Sustainability in Corrugated Packaging

Corrugated boxes lead the way in recycling.

- In the U.S., corrugated boxes achieved a recovery rate above 93% in 2022 (EPA).

- In أوروبا, PPWD mandates that all packaging must be recyclable or reusable by 2030.

- In أستراليا, 100% of packaging must be recyclable, compostable, or reusable by 2025 under APCO.

Consumers also care: NielsenIQ’s 2023 report shows 78% of global consumers are willing to change brands for more eco-friendly packaging (source).

At Packccp, we supply FSC-certified materials, soy-based inks, and recyclable coatings, helping brands meet compliance without sacrificing aesthetics.

Final Thoughts

From fibre sourcing to recycling, corrugated cardboard box making combines engineering with sustainability. Each step—steam conditioning, flute forming, adhesive bonding, and finishing—ensures packaging is lightweight yet durable, cost-effective yet eco-friendly.

For B2B brands, choosing the right partner means more than just sourcing cartons—it’s about creating packaging that protects, communicates, and complies.

👉 At Packccp, we design corrugated and rigid paper boxes tailored for U.S., European, and Australian markets. Whether you need durable e-commerce cartons or luxury corrugated gift boxes, we help you achieve functionality with a premium finish. اتصل بنا to request a sample or consultation.

FAQ: Corrugated Cardboard Box Production

1. What materials are used to make corrugated cardboard boxes?

Mostly kraft linerboard and recycled fluting medium, bonded with starch-based adhesives.

2. How strong are corrugated boxes compared to wooden crates?

Triple-wall corrugated boxes can replace wooden crates in many export applications due to their high compression strength.

3. Are corrugated boxes eco-friendly?

Yes. They are recyclable, renewable, and often made from over 90% recycled content in North America.

4. Can corrugated boxes be customized for branding?

Absolutely. الطباعة, embossing, and eco-coatings allow boxes to carry logos, sustainability messages, and premium finishes.

5. Why choose packccp as a supplier?

Because we combine regional compliance expertise (U.S., EU, AU) with tailored design, FSC-certified materials, and scalable B2B solutions.