هل سبق لك أن تساءلت عن كيفية صناعة الصناديق المموجة التي تحمي منتجاتك؟? تعتبر هذه الصناديق ضرورية في صناعة التعبئة والتغليف لأنها قوية, فعالة من حيث التكلفة, وصديقة للبيئة. إن تعلم كيفية إنتاجها يمنحك رؤية واضحة لما يحدث داخل المصنع. في هذه المقالة, نحن نرشدك خلال كل مرحلة, من المواد الخام إلى اختبارات الجودة, يوضح كيف تضمن المعايير الدولية الاتساق, تغليف موثوق.

المواد الأساسية: مما تصنع الصناديق المموجة?

المادة الرئيسية للصناديق المموجة هي ورق الكرافت, تقدر بقوتها ومتانتها. أعتقد أنه يمكنك فقط الاستيلاء على أي قطعة من ورق الكرافت وصنع صندوق مموج? ليس تمامًا، فقط الدرجات ذات طول الألياف المناسب, قوة الشد, والانتهاء من السطح - غالبًا ما يجتمع ISO 536 و قبعات T410– مناسبة للإنتاج. يتكون اللوح المموج القياسي من جزأين:

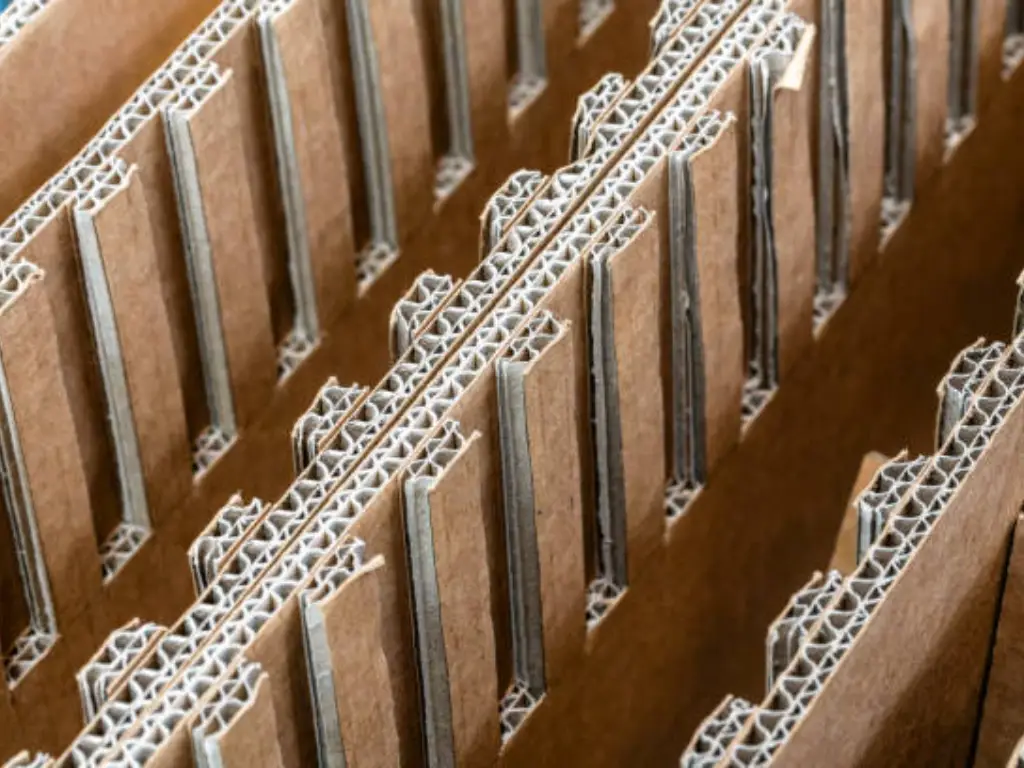

- بطانة: الطبقات الخارجية المسطحة, مصنوعة من لب كرافت البكر للقوة ومقاومة الماء أو الألياف المعاد تدويرها من أجل التكلفة والاستدامة.

- المتوسطة المموجة: الطبقة الداخلية المخددة التي توفر الصلابة, عادة ما تكون مصنوعة من لب شبه كيميائي لتحقيق التوازن بين المرونة ومقاومة السحق.

تستخدم بعض اللوحات المتخصصة بطانات مغلفة بالبولي, الشمع, أو إضافات مقاومة للماء لتطبيقات مثل الأطعمة المجمدة أو المواد الكيميائية. تؤثر المادة بشكل مباشر على قوة الصندوق وأدائه, تمهيد الطريق لفهم كيفية صنع الصناديق المموجة في المصنع.

عملية تصنيع الصناديق المموجة خطوة بخطوة

إن صنع الصناديق المموجة في المصنع هي عملية تتم خطوة بخطوة حيث يتم تصنيع الورق, آلات, وتعمل الأتمتة معًا لتحقيق التوازن بين السرعة والدقة. وإليك كيفية تحويل ورق الكرافت إلى قوة, تغليف موثوق:

1. المموج المتوسطة

تبدأ العملية بلفات من الورق المتوسط. يتم معالجتها بالحرارة والبخار لجعل الألياف مرنة. ثم تمر الورقة عبر المموج, آلة سريعة ذات لفات محززة تضغط الورق على شكل مزامير تشبه الموجة. هذه المزامير هي التي تعطي الصناديق المموجة قوتها.

2. تطبيق لاصق

التالي, يتم تطبيق غراء قائم على النشا، غالبًا ما يكون مصنوعًا من الذرة أو القمح. تحت الحرارة والضغط الخاضعة للرقابة, يتم ربط المزامير بالصفيحة المسطحة الأولى من البطانة. وهذا يخلق ما يعرف بلوحة الوجه الواحد.

3. تشكيل لوحة الحائط المفردة والمزدوجة

تتحرك اللوحة ذات الوجه الواحد للأمام ويتم ربطها ببطانة أخرى في الخلف. يؤدي هذا إلى إنشاء ورقة كاملة من الكرتون المضلع, المعروفة بالجدار الواحد. للتغليف الثقيل, يتم إضافة المزيد من الطبقات لتشكيل ألواح حائط مزدوجة أو حتى ثلاثية.

4. التجفيف والمعالجة

ثم تنتقل اللوحة الجديدة عبر الألواح الساخنة. تعمل هذه الخطوة على تجفيف الغراء وتثبيت الهيكل في مكانه. تقوم الأنظمة الآلية بفحص درجة الحرارة باستمرار, التسطيح المجلس, وخطوط الغراء للحفاظ على الجودة متسقة.

5. الحز والتسجيل

يتم قطع الصفائح الطويلة من الكرتون المضلع إلى العرض الصحيح ويتم تسجيلها بخطوط مطوية. وهذا يجعل من السهل طي الأوراق لاحقًا مع ضمان أن كل صندوق موحد, حتى عندما يتم إنتاج الآلاف.

6. قطع يموت والطباعة

تحتاج بعض الصناديق إلى أشكال أو علامات تجارية خاصة. في هذه الحالات, تمر الأوراق من خلال قواطع القالب الدوارة للحصول على قطع مخصصة. في نفس الوقت, يمكن للطابعات الفلكسوغرافية تطبيق الشعارات, علامات التعامل, أو التصميمات باستخدام الأحبار المائية - كل ذلك يتم بتمريرة سريعة واحدة.

7. للطي واللصق

أخيراً, يتم نقل الأوراق إلى آلة لصق المجلدات. هنا يتم طيها, لصقها, ومجمعة في أكوام مسطحة. غالبًا ما تتولى الأذرع وأجهزة الاستشعار الآلية عملية الفحص والتحريك, ضمان شحن الصناديق الخالية من العيوب فقط.

من البداية إلى النهاية, يوضح هذا التدفق كيف تجمع المصانع الحديثة بين المواد والآلات الذكية لإنتاج الصناديق المموجة على نطاق واسع. والنتيجة هي تغليف قوي, قابل للتخصيص, ومتسقة وجاهزة لحماية المنتجات في كل صناعة.

معايير تصميم الصندوق والأنواع الهيكلية

يؤثر تصميم الصندوق على قوة التراص, منطقة قابلة للطباعة, مقاومة الانفجار, وتكلفة الإنتاج. الاتحاد الأوروبي لمصنعي الألواح المموجة (فيفكو) يستخدم نظام الترميز القياسي للتجارة الدولية. يوضح الجدول هياكل الصناديق المشتركة, أنواع الفلوت, والنموذجية الخاصة بهم استخدامات الصناعات.

| نوع الفلوت & هيكل الجدار | أنماط الصندوق المشترك | التطبيقات النموذجية |

| الفلوت (تقريبا. 4.8 مم) جدار واحد | RSC (حاوية مشقوقة عادية) | البضائع الهشة, الأجزاء الصناعية, الإلكترونيات مع احتياجات التوسيد |

| ب الفلوت (تقريبا. 2.5 مم) جدار واحد | فول (التداخل الكامل مشقوق) | المنتجات الثقيلة أو الكثيفة, التراص أفضل ودعم الحافة |

| ج الناي (تقريبا. 3.6 مم) جدار واحد | شهادة الثانوية العامة (حاوية نصف مشقوقة) | تخزين بالجملة, عناصر التحميل العلوي, صواني البيع بالتجزئة |

| والفلوت (تقريبا. 1.2 مم) جدار واحد أو مزدوج | صناديق مقطوعة بالقالب (على سبيل المثال. مربع البريد) | التعبئة والتغليف للتجارة الإلكترونية, يعرض البيع بالتجزئة, علب الهدايا |

| قبل الميلاد الناي (جدار مزدوج: ب+ج) جدار مزدوج | RSC / فول / صواني مخصصة | التعبئة والتغليف الثقيلة, السيارات, شحن التصدير |

| إي بي فلوت (جدار مزدوج: ه+ب) جدار مزدوج | تغليف جاهز للرف | طباعة جرافيكية عالية, التعبئة والتغليف في نقاط البيع, الالكترونيات الاستهلاكية |

| الجدار الثلاثي (AAA أو AAC) الجدار الثلاثي | صناديق البليت, صناديق السائبة | الآلات الصناعية, البضائع الخطرة, الشحن لمسافات طويلة |

تقنيات الطباعة والتخصيص المستخدمة في المصانع

التخصيص يعد جزءًا مهمًا من إنتاج الصناديق المموجة, خاصة عندما تحتاج التعبئة والتغليف إلى دعم كل من الخدمات اللوجستية والعلامات التجارية.

طرق الطباعة:

● طباعة فلكسوغرافية: تقوم الألواح المطاطية المرنة بنقل الحبر المائي مباشرة إلى اللوحة. إنه سريع, فعالة من حيث التكلفة, ومناسبة للشعارات البسيطة أو تعليمات التعامل مع الطلبات بالجملة.

● الترقق الحجري: تتم طباعة الرسومات عالية الدقة على أوراق منفصلة ثم يتم لصقها على اللوحة. توفر هذه الطريقة جودة صورة ممتازة لتغليف التجزئة أو العرض المتميز.

● تقنيات أخرى: الطباعة الرقمية, ما قبل الطباعة, والشاشة الحريرية تسمح بجولات صغيرة, ألوان دقيقة, أو القوام الخاص.

المعالجات السطحية:

● الورنيش وطلاء الأشعة فوق البنفسجية: يحمي الصندوق من الرطوبة ويجعل الطباعة تدوم لفترة أطول.

● طلاء الشمع أو بولي: يضيف مقاومة للماء والشحوم, مثالية لتغليف المواد الغذائية أو سلسلة التبريد.

● قطع النوافذ والتثقيب: يحسن الوظائف ويسمح بعرض أفضل للمنتج.

التخصيص يتجاوز الطباعة. توفر الشركات المصنعة مثل Packccp خيارات لشكل الصندوق, مقاس, لون, مُكَمِّلات, وإدراج, السماح للعلامات التجارية بإنشاء عبوات تلبي احتياجات تسويقية ولوجستية محددة.

مراقبة الجودة واختبارها في إنتاج الصناديق المموجة

يتم تشغيل مراقبة الجودة في جميع أنحاء التصنيع للتحقق من الأداء في ظل ظروف المناولة والتخزين. تشمل اختبارات الصناعة الشائعة:

- اختبار سحق الحافة (علاج بالصدمات الكهربائية): يقيس قوة الضغط على طول الحافة المخددة, يوضح مدى جودة تعامل الصندوق مع ضغط التراص.

- اختبار قوة الانفجار: يتحقق من مقاومة التمزق تحت ضغط موحد, ضمان قدرة الصندوق على الاحتفاظ بمحتوياته دون تمزق.

- اختبار السحق المسطح: تختبر قوة الناي عن طريق الضغط بشكل عمودي على اللوحة, مهم للصلابة تحت الحمل.

- اختبار كوب: يقيس امتصاص الماء لضمان مقاومة الرطوبة في البيئات الرطبة أو المبردة.

يستخدم الإنتاج الحديث أيضًا أنظمة فحص آلية للكشف عن أعطال الغراء, عيوب الطباعة, ويخطئ في الوقت الحقيقي. وهذا يضمن أن كل صندوق يلبي المعايير الهيكلية والمرئية قبل الشحن.

الاستدامة واتجاهات التصنيع الذكية

تستخدم المصانع التي تنتج الصناديق المموجة بشكل متزايد الأنظمة الذكية والممارسات الصديقة للبيئة. تساعد هذه التحسينات على تقليل النفايات, توفير الطاقة, وتعزيز الكفاءة الشاملة.

الممارسات المستدامة

- استخدام المواد الورقية المعتمدة من FSC

- الأحبار المائية والمواد اللاصقة الحيوية

- إعادة تدوير مياه الصرف الصحي وأنظمة استعادة الحرارة

- الامتثال لمعايير ISO 14001 للإدارة البيئية

اتجاهات التصنيع الذكية

- آلات التموج وأدوات لصق المجلدات التي تدعم إنترنت الأشياء

- مراقبة الجودة المعتمدة على الذكاء الاصطناعي وتحليلات وقت التوقف عن العمل

- التوائم الرقمية لمحاكاة العمليات في الوقت الحقيقي

- تخصيص دفعة صغيرة مدعوم بقوائم انتظار المهام المستندة إلى السحابة

تدمج المصانع الآن الأنظمة الذكية والممارسات الصديقة للبيئة, جعل العمليات أكثر كفاءة واستدامة. بدءًا من اختيار ورق الكرافت المناسب وتشكيل الألواح المخددة وحتى الطباعة, قابلة للطي, واختبار صارم, تضمن كل خطوة أن الصناديق تلبي المعايير الهيكلية والبصرية. Packccp يسلم دائم, تغليف صديق للبيئة معتمد من SGS وFSC, تزويد الشركات بحلول عالية الجودة تدعم الاحتياجات اللوجستية وعرض العلامة التجارية.

اتصل بنا للحصول على موثوقة, مخصص دليل شراء الصناديق المموجة لاحتياجاتك الصناعية أو التجزئة!