Made From Kraft Paper, Recycled Paper, or Coated Paper for Durability and Eco-Friendly

Always Biodegradable and Recyclable, Emphasizing Sustainability, Reducing Environmental Impact

Often Affordable for Retail and Food Service Sectors

Helps Decrease Reliance on Plastic Bags, Supporting Environmental Sustainability

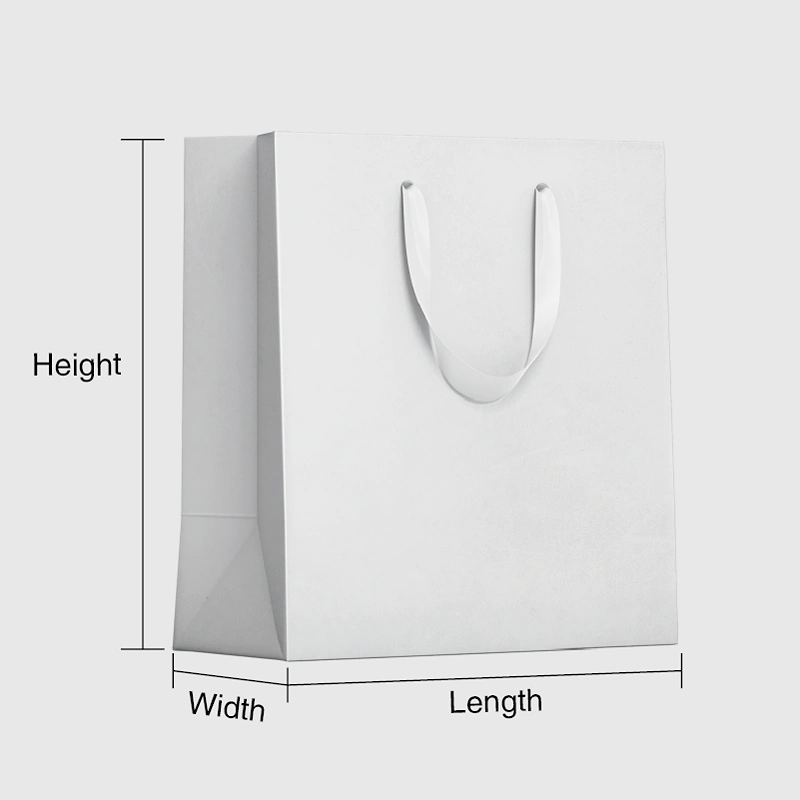

You can customize your packaging size to well fit your product.

Any size, Any Designs.

Heiderberg CX104 6-Color Offset Printing Machine

Komori Lithrone GX40 advance Offset UV Printing Machine

Eco-Friendly & Sustainability

Lower VOC Emissions

Vibrant Colors

Eco-friendly ,recycable, , Biodegradable , FSC certified paper is available

You are free to choose your design colors, including CMYK, Pantone, metallic colors, and white.

Printing quality is affected by paper flatness, moisture absorption, surface smoothness, ink quality and printing process and other aspects. Selection of appropriate printing equipment and processes, reasonable control of the printing environment and paper storage conditions can significantly improve the quality of printing.

Select paper and coatings that meet the standards for food contact materials, avoid the use of chemicals containing heavy metals and other hazardous substances, and strictly control the production environment and processes to ensure that paper packaging does not contaminate food during manufacture, storage and use.

Different corrugated shapes are selected according to the weight, shape and transportation conditions of the product. A flute is suitable for packaging heavy objects that require strong support, B flute is more suitable for packaging small commodities, C flute is suitable for a wide range of applications, taking into account both cushioning and support, and E and F flute are suitable for packaging high-end fine products.

Our packaging production is all in China, the specific location depends on the different types of packaging.

Different Knotting Methods and Materials for the Handles of Paper Bags Can Significantly Influence Their Design and Style

250gsm to 300gsm

250gsm to 300gsm

250gsm to 300gsm

250gsm to 300gsm

250gsm to 300gsm

100gsm to 150gsm

100gsm to 150gsm

Material: Grosgrain

Material: Silk Ribbon

Material: Rope with Plastic End

Material: Woven

Material: Twisted Paper

Material: Flat Paper

Material: Rope

Welcome to use PACKCCP services, we are the China manufacturer in printing and packaging business for over 30 years. you will find it easy job to communicate with our experienced sales with fully understanding your packaging needs. Our team will fully support you in designing, sample making ,production and shipping.

You can select the dieline from our vast options or tell us the products you need to pack and we can give you packaging solutions.

After confirming the box style and size, material, quantity our sales will offer quotation.

We can provide custom dieline for your designer to create the artwork, after confirming the artwork, our engeering team will help you in sample based on your custom design ,size and production material

We will send you sample by express to confirm the sample quality, if order is confirmed, we will arrange PI for you to arrange deposit.

After receiving your deposit, we will arrange sample and final product production right away.

You can either use your own forwarder or our forwarder to ship out the goods.

no mater it is EXW, FOB, CIF, DDU or DDP or ship to your supplier to assemble the products, we are experienced in all .

Printing quality is affected by paper flatness, moisture absorption, surface smoothness, ink quality and printing process and other aspects. Selection of appropriate printing equipment and processes, reasonable control of the printing environment and paper storage conditions can significantly improve the quality of printing.

Select paper and coatings that meet the standards for food contact materials, avoid the use of chemicals containing heavy metals and other hazardous substances, and strictly control the production environment and processes to ensure that paper packaging does not contaminate food during manufacture, storage and use.

Different corrugated shapes are selected according to the weight, shape and transportation conditions of the product. A flute is suitable for packaging heavy objects that require strong support, B flute is more suitable for packaging small commodities, C flute is suitable for a wide range of applications, taking into account both cushioning and support, and E and F flute are suitable for packaging high-end fine products.

Our packaging production is all in China, the specific location depends on the different types of packaging.

*All your information are respected & protected in Packccp.